Maintenance and Precautions of Co2 Laser Cutter

Replacement and Cleaning of Water Tank

Before starting the co2 laser machine, make sure the laser tube is filled with circulating water. The quality and temperature of circulating water directly affect the service life of the laser tube. It is recommended to use pure water and keep the water temperature below 35°C. If more than 35°C, need to replace the circulating water or add ice in the water to reduce the water temperature (users are advised to choose the cooler, or use two tanks).

Clean water tank: First, turn off the power, pull out the inlet water pipe, so that the water in the laser tube into the water tank automatically. Secondly, open the water tank, remove the water pump, clean up the sewage on the pump. Thirdly, clean the water tank, replace the circulating water, return the pump to the tank, insert the pipe connected to the pump into the water inlet, and clean the joint. Finally, leave the pump and run for 2-3 minutes (filling the laser tube with circulating water).

Blower Cleaning

Long-term use of fans will lead to a large number of solid dust accumulation, resulting in lots of noise, not conducive to exhaust, deodorization. When the FAN has no suction, first turn off the power, remove the inlet and outlet from the fan to remove the dust, and then turn the fan upside down and pull the blades in until it is clean. Finally, install the fan.

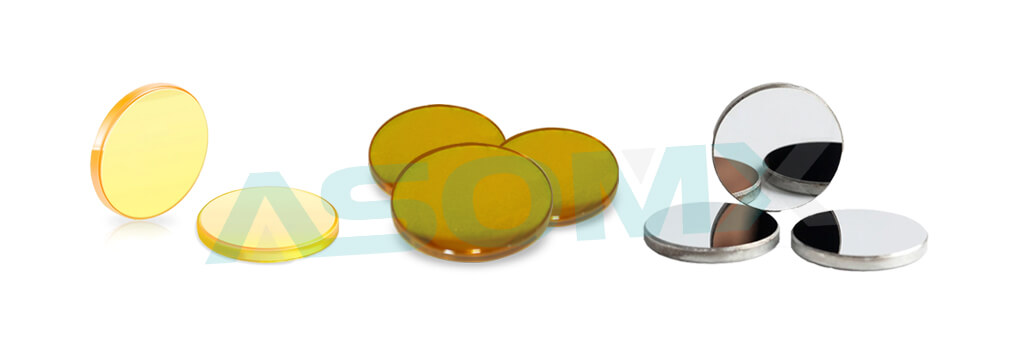

Laser Lens Cleaning

The laser engraving machine has three mirrors and a focusing lens (the first mirror is at the exit of the laser tube, the upper left corner of the machine, and the second mirror is at the left end of the beam. The third mirror is located on the top of the fixed part of the laser head, the focusing mirror is located in an adjustable tube at the lower part of the laser head). The laser light is reflected and focused by these lenses and is emitted from the laser head. Lenses are prone to dust or other contaminants, resulting in laser wear or lens damage. Do not remove No.1 and No.2 lenses when cleaning. Instead, carefully wipe the lens with a cleaning fluid along the center of the lens. Edge rotary wiper. The No.3 lens and the focusing lens need to be removed from the frame and polished in the same way.

Note: First, the lens gently wipe, the surface coating should not be damaged; Second, the process should be handled gently to prevent dropping; Third, the installation of focusing lenses, keep concave face down.

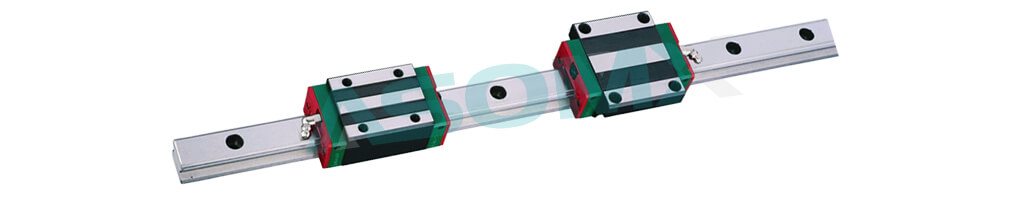

Rail Cleaning

Guide rail and the linear shaft are one of the core components of the CNC laser machine, with guidance and support functions. In order to guarantee the machine tool has the higher processing precision, requests its guide rail, the straight-line guide rail to have the higher guiding precision and the good movement stability. During the operation of the equipment, a great deal of corrosive dust and smoke will be produced when the workpiece is processed. The dust will accumulate on the surface of the guideway and linear axis for a long time, which has a great influence on the machining accuracy of the equipment. The erosion point is formed on the surface of the linear guide rail, which shortens the service life of the equipment. In order to make the machine work normally and ensure the processing quality of the products, it is necessary to do well the routine maintenance work of the guide rail and the linear shaft.

Screw and Coupling Fastener

After a period of work, the movement of the system screws and coupling will be loose, affecting the stability of the mechanical movement. Therefore, in the process of laser machine operation, it is necessary to observe whether there is abnormal noise or abnormal phenomenon of transmission parts, and timely maintenance and repair. At the same time, the machine should use tools to tighten the screws one by one. The first firmness check should be about one month after the equipment is in use.

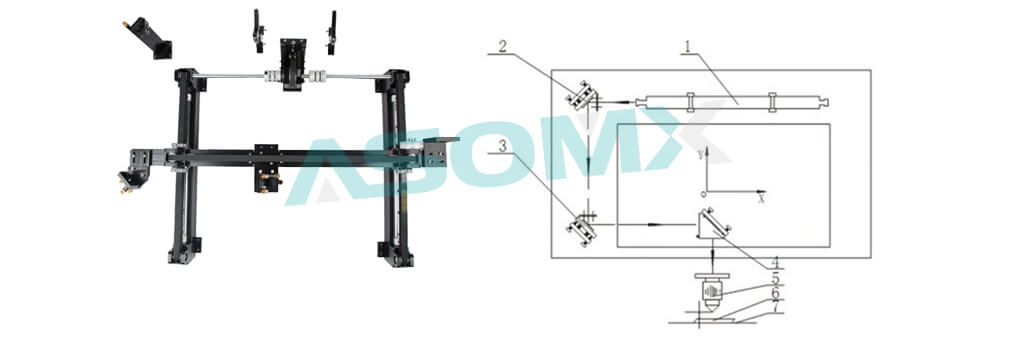

Light Path Inspecting

The light path system of the laser engraving machine is completed by the reflection mirror and the focusing lens. The optical path of the focusing lens has no deviation problem, the three-mirror is fixed by the mechanical part, the deviation is even more impossible, although under normal circumstances will not be offset, users are advised to check whether the optical path is normal before each work.

Related Models: AE-M Series · AE-H Series

Video Reference

Please Share This

Get A Quick Quote Today!