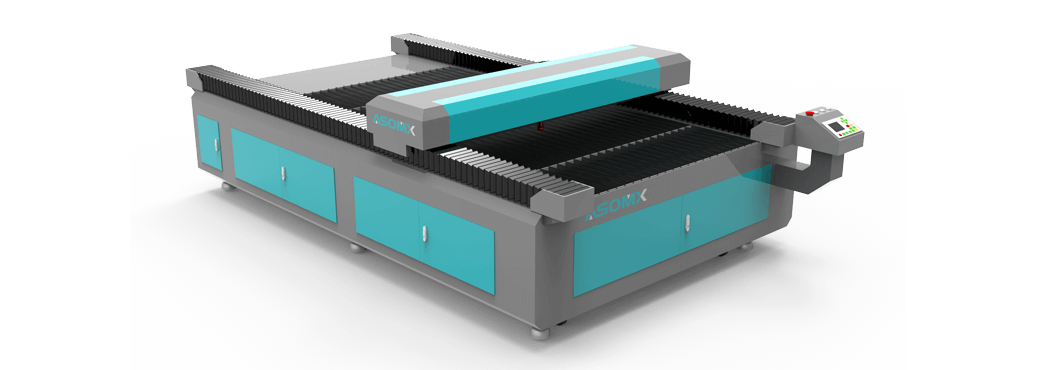

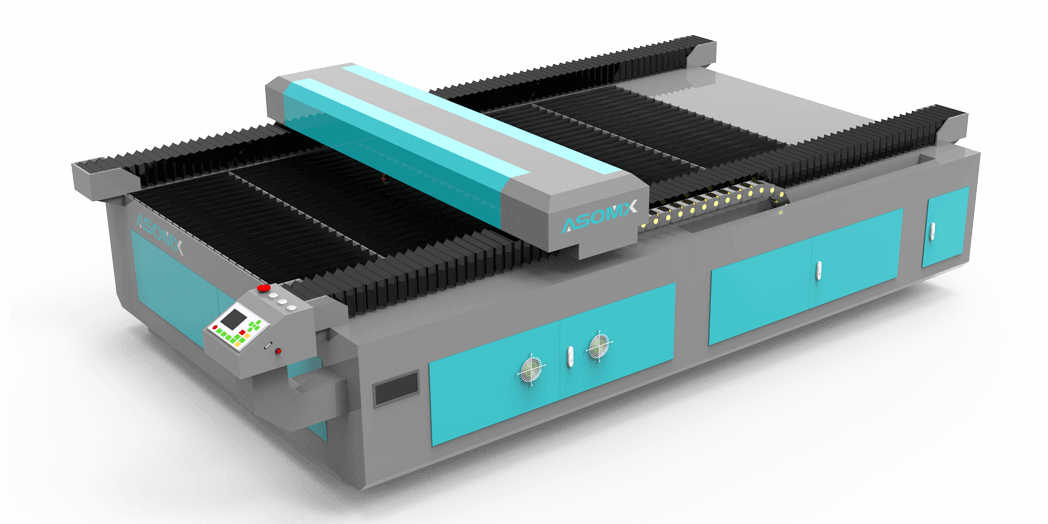

Features of Hybrid Laser Cutting Machine

- The cutting section is excellent, the precision is high, the stability is good, satisfies the precision part processing request. Stable dynamic performance allows continuous operation for long periods of time.

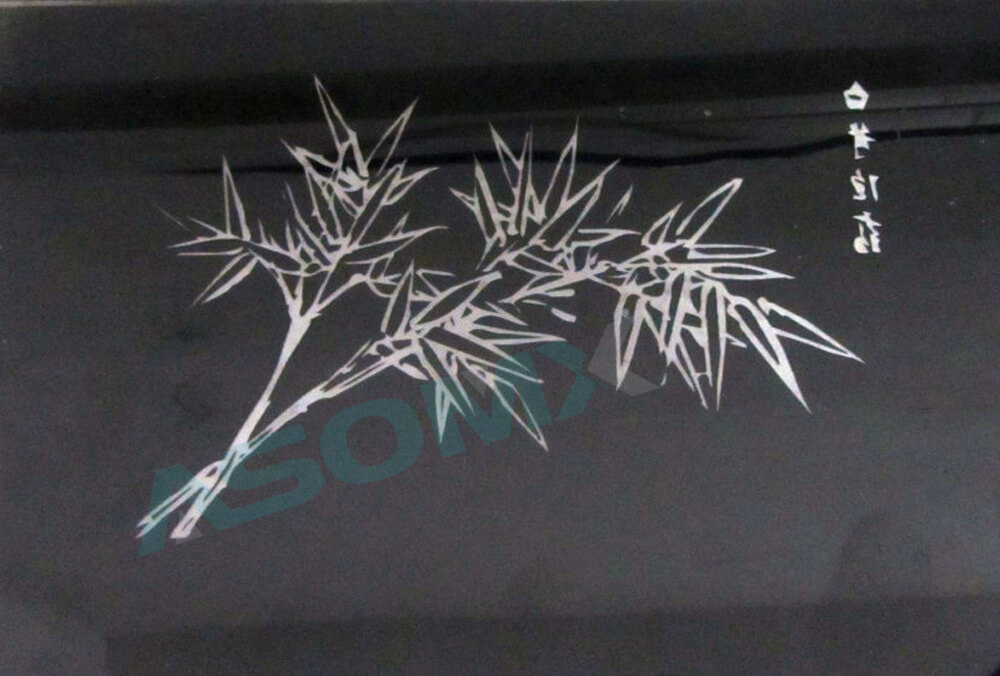

- Capable of cutting both non-metal and metal, able to cut stainless steel, carbon steel, also can cut acrylic, wood, MDF, PVC board, paper, fabric, etc.

- Mechanical follow-up cutting head system, the cutting head always follows the material, keeps the cutting point position unchanged, automatically adjusts the height along the metal plate surface, when the metal plate is not flat, the dynamic focusing laser cutting head automatically adjusts the focusing distance, to ensure that the cutting part smooth, no further processing.

- Precision ball screw drive mechanism and optimized CNC system control, greatly improve the response speed and cutting accuracy, extend the service life.

- Stable optical design, with high-power industrial water chiller cooling CO2 laser tube, to ensure the laser output stability and the laser power of large-format cutting surface is the same, stable processing quality.

- Open blade worktable is made of special treated material, which is not easy to wear and tear, suitable for all kinds of hard materials.

- Adopts Machine tool-class Chassis to ensure the stability and accuracy of high-speed machining.

- Professional cutting software is designed for metal and non-metal cutting, high compatibility, support most computer operating systems.

- Non-contact height adjustment structure, material no mechanical extrusion or mechanical stress, no knife marks, processing parts surface no damage, no deformation, can cut all materials at the lowest cost.

- The machine adopts constant light path design, equipped with an anti-reflection system, effectively protect the laser tube.

- Adopt Taiwan HIWIN linear guide rail and precision gear, cooperate with advanced DSP controller to control three-phase stepping motor, ensure better stability and precision during high speed running and working.

- Using USB interface and large capacity storage device, support hot swap and instantaneous data transmission, without computer resources to achieve high efficiency, LCD control panel, friendly man-machine interface, easy to operate, greatly increased the speed and efficiency of work.

- Solenoid valve allows gas blowing only during cutting to avoid gas wasting. The valve is particularly important for oxygen assistance during metal cutting.

Product Details and Configuration

All the details and configuration can be customized according to your processing requirements

Control panel

1 of 9Laser head

2 of 9CO2 laser tube

3 of 9Display

4 of 9Control button

5 of 9Working table

6 of 9Guide rail

7 of 9Control cabinet

8 of 9Movable wheel

9 of 9Technical Parameters

| Model No. | AE-M Series |

|---|---|

| Laser Power | 150W/180W/280W/300W |

| Laser Wavelength | 10.64μm |

| Laser Type | Hermetic and Detached CO2 Laser Tube |

| Scanning Precision | 4000DPI |

| Working Range | 1300mm*2500mm |

| Optional Range | 1300mm*900mm / 1600mm*1000mm |

| Min. Engraving Size | English Letter: 1.0mm*1.0mm |

| Dichromatic Cutting | Up to 256 colors |

| Engraving Speed | 0-60000mm/min |

| Cutting Speed | 0-50000mm/min |

| Control System | Leetro System/Ruida System |

| Control Software | Laser cut/Laser work |

| Repeatability Accuracy | ±0.01mm |

| Cooling Type | Circulating Water Cooling |

| Graphic Format Supported | DST, PLT, BMP, DXF, DWG, AI, JPG, GIF, PGN, TIF, LAS, etc. |

| Compatible Software | TAJIMA, CORELDRAW, PHOTOSHOP, AUTOCAD, ARTCUT, etc. |

| Electricity Supply | 110V/220V±10% 50/60Hz |

| Unit Power | 2.2kw |

| Working Environment | Clean or Dust free |

| Operating Temperature | 0°C-45°C |

| Working Humidity | 5%-95% no condensed water |

| Laser Module Life | 15000hours |

| Gross Weight | 700kg |

| Package Dimensions | 3350*2220*1350mm |

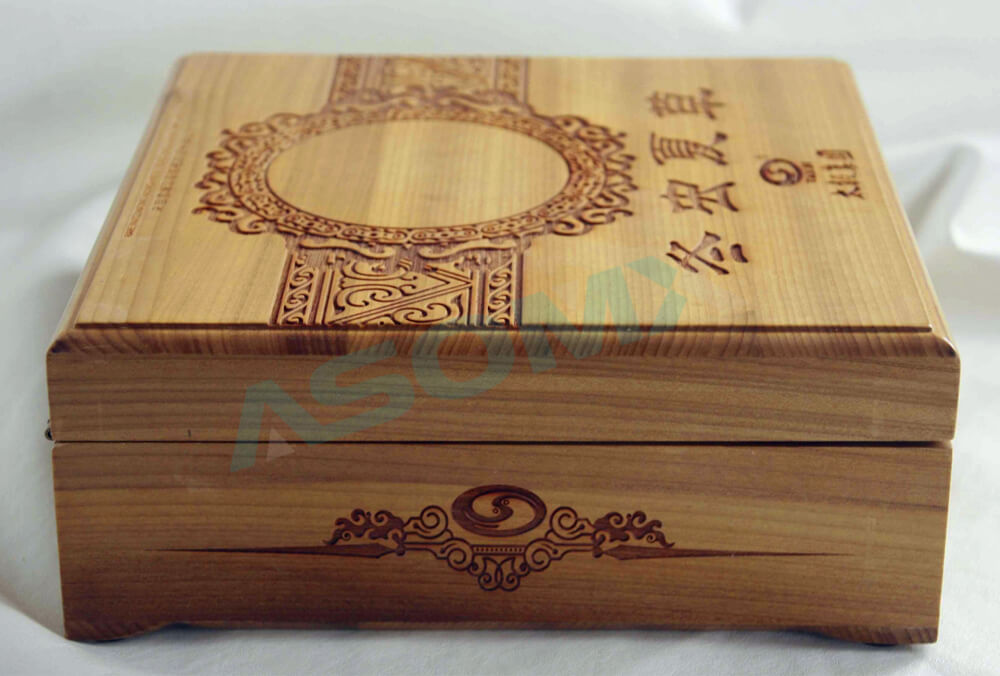

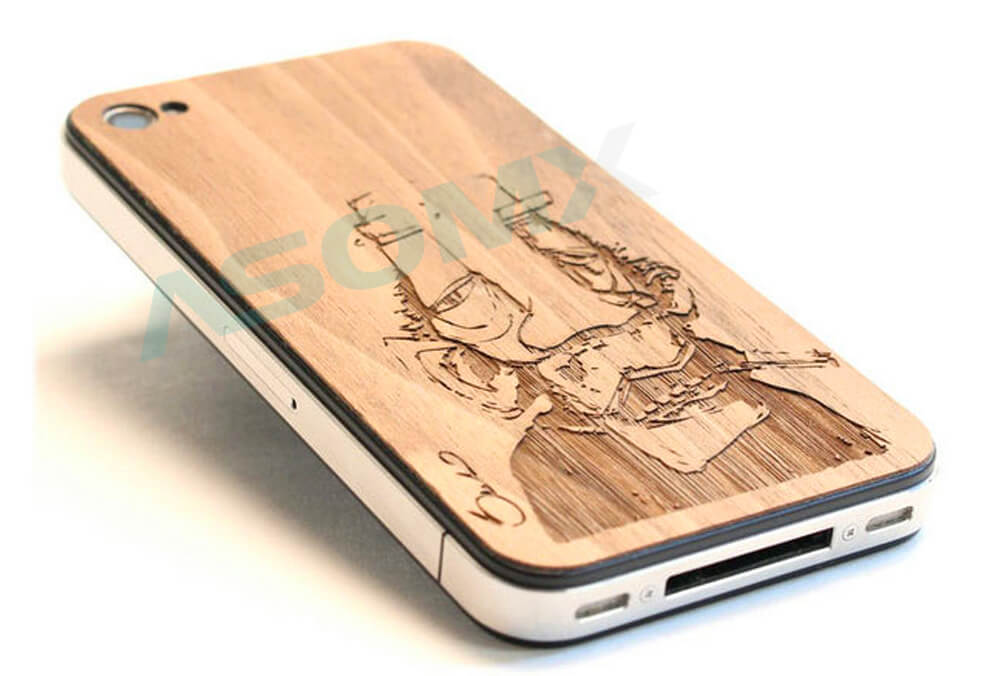

Delivering professional-level results

Industrial-grade components give you faster motion, better accuracy and increased laser power

Engraving and Cutting achieve perfect unity

Found a wide range of multi-purpose lasers for precision cutting and engraving

Contact Us

Get your free quote, expert advice today.