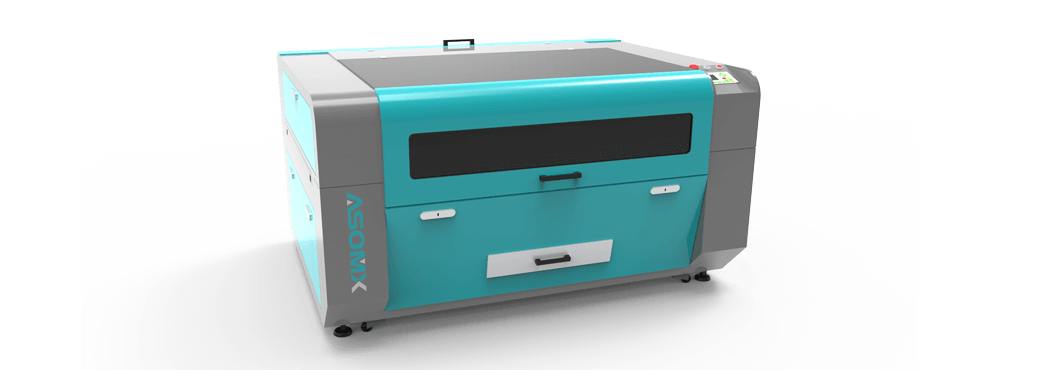

Features of Hobby Laser Cutting Machine

- Laser engraving machine operation interface is simple, supports PC and USB 2.0 connection, advanced LCD screen control panel, DSP offline control system.

- Chassis sealed design to ensure the safety of the processing environment, unique cover protection function, operators open laser engraving machine cover, the laser power will be suspended to protect the safety of operators.

- The precise positioning and visual working path of the laser beam are realized by red light indication, which is convenient for the operator to obtain the specific machining position.

- Two kinds of worktable can be selected, the processing of acrylic, wood and other hard materials, suitable for aluminum alloy blade worktable, leather, cloth and other soft materials, suitable for honeycomb worktable, keep the material as flat as possible to ensure the cutting effect.

- Motorized up-down platform is optional to allow customers adjust the height of the worktable through the operation of the Z axis to achieve thick material processing, the Z axis lifting function is essential when using autofocus and rotary axis tools.

- The chuck rotary platform is designed to engrave irregular objects, can be selected for cylinder engraving.

- Imported high precision linear guide rail, professional optical system, improve the quality of engraving, extend the machine life.

- High strength mechanical structure machine body, ensure the smooth operation of the machine, long-term work without adjustment.

- Unique front and rear through design, special door for unlimited engraving material through.

- The cutting software can cooperate with the graphics processing software such as AutoCAD and CorelDraw, directly output the original image, which is more suitable for the user's field design requirements.

- Freely define the engraving order, easy to realize all or part of one-time output, USB interface is used to transfer data, built-in large capacity memory, greatly improve the working speed and efficiency.

- DSP control system provides continuous, fast, curve cutting, the shortest processing path optimization, and other functions to achieve high-speed cutting.

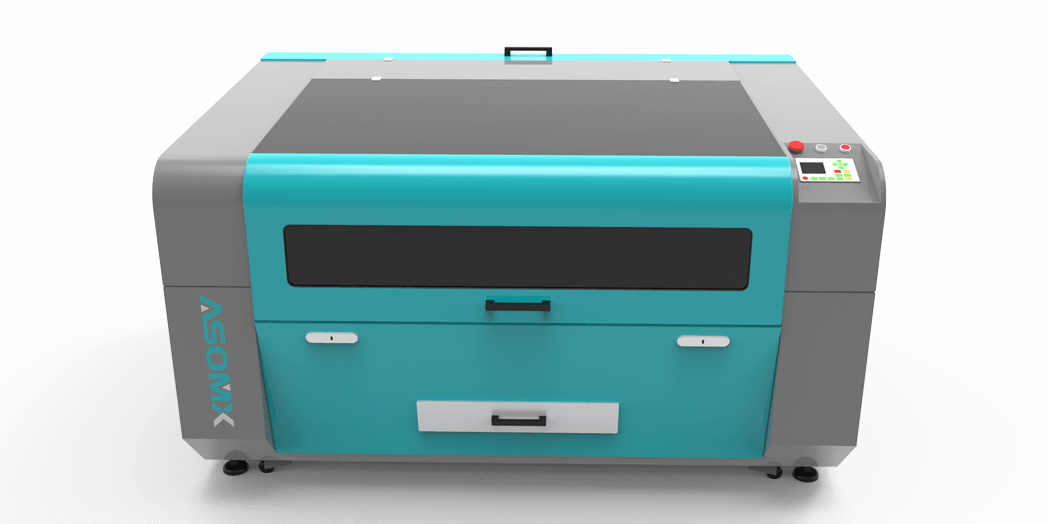

Product Details and Configuration

All the details and configuration can be customized according to your processing requirements

Control panel

1 of 8Protective glass

2 of 8CO2 laser tube

3 of 8Collecting drawer

4 of 8Control button

5 of 8Open handle

6 of 8Control cabinet

7 of 8Movable wheel

8 of 8Technical Parameters

| Model No. | AE-X Series |

|---|---|

| Laser Power | 100W/130W/150W/180W |

| Laser Wavelength | 10.64μm |

| Laser Type | Hermetic and Detached CO2 Laser Tube |

| Scanning Precision | 4000DPI |

| Working Range | 1300mm*900mm |

| Optional Range | 600mm*900mm / 1600mm*1000mm |

| Min. Engraving Size | English Letter: 1.0mm*1.0mm |

| Dichromatic Cutting | Up to 256 colors |

| Engraving Speed | 0-60000mm/min |

| Cutting Speed | 0-50000mm/min |

| Control System | Leetro System/Ruida System |

| Control Software | Laser cut/Laser work |

| Repeatability Accuracy | ±0.01mm |

| Cooling Type | Circulating Water Cooling |

| Graphic Format Supported | DST, PLT, BMP, DXF, DWG, AI, JPG, GIF, PGN, TIF, LAS, etc. |

| Compatible Software | TAJIMA, CORELDRAW, PHOTOSHOP, AUTOCAD, ARTCUT, etc. |

| Electricity Supply | 110V/220V±10% 50/60Hz |

| Unit Power | 1.2kw |

| Working Environment | Clean or Dust free |

| Operating Temperature | 0°C-45°C |

| Working Humidity | 5%-95% no condensed water |

| Laser Module Life | 15000hours |

| Gross Weight | 430kg |

| Package Dimensions | 1950*1930*1270mm |

Delivering professional-level results

Industrial-grade components give you faster motion, better accuracy and increased laser power

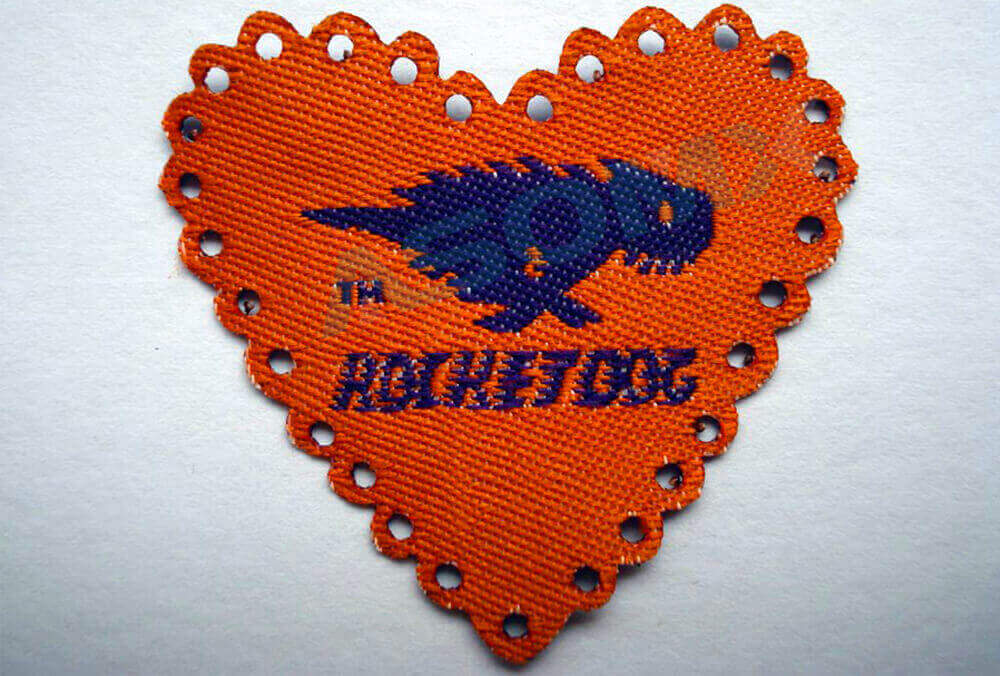

Engraving and Cutting achieve perfect unity

Found a wide range of multi-purpose lasers for precision cutting and engraving

Contact Us

Get your free quote, expert advice today.