Common quality problems and solutions in the continuous fiber laser machine processing of steel plates

Slag appears after a period of laser machine processing

The main reason is that molten metal can not flow smoothly out of the slit. The possible reasons are laser head optical path problems, cutting gas flow changes, and be processed sheet temperature changes. At this time, the width of the slit can be compared between the quality degraded part and the non-degraded part. If the slit width is different, it means that the lens of the cutting head as temperature drift or the lens is dirty, which causes the actual focus position and center of the laser to shift. This requires checking whether the temperature of the collimating and focusing lens of the cutting head is normal, whether the lens of the laser head is dirty, and correcting the center degree again.

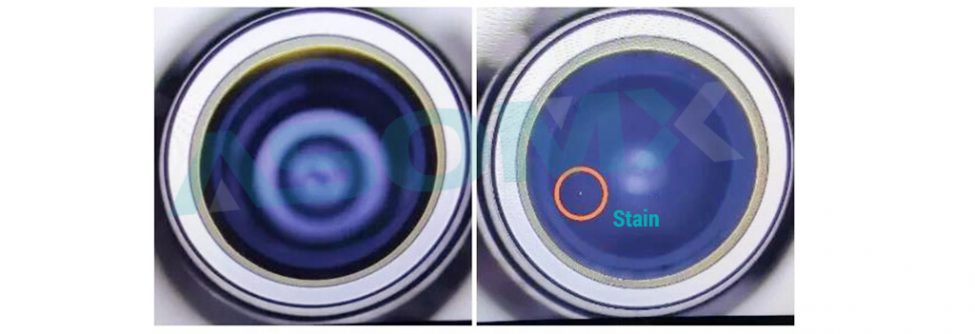

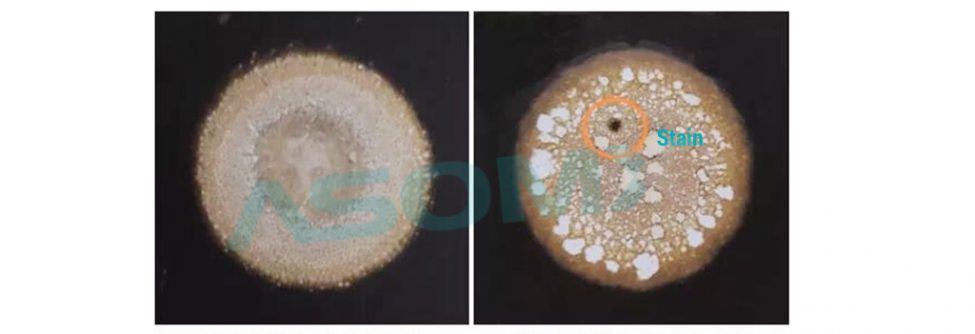

The laser cutting head and the optical lens in the cutting head require a high degree of cleanliness, any small impurities or scratches may cause serious damage. The lens must be cleaned and removed in a dust-free environment. The laser cutting head was observed under microscope ≥20 times and wiped with dust-free cotton swab and ethanol. Do not disassemble optical components without permission and without the conditions to disassemble them.

Overburn after a period of laser cutter processing

The main reason is the change of related conditions such as sheet temperature, cutting gas and laser head. When processing thick plates for a long time, due to the relatively slow processing speed, the heat accumulation of the plate causes the temperature of the material to rise, which leads to over-burning, it may also be caused by the temperature drift of the lens on the optical path or the dirty lens that causes the laser focus position drift and changes in the distribution of light spots irradiated to the material, causing excessive accumulation of energy and burn. At this time, you should check whether the lens in the laser head is clean, whether the lens temperature has changed significantly, whether the nozzle center is offset. If the problem cannot be solved after confirming the above aspects, need to consider whether the laser output head abnormal situation(such as dot or condensation).

Laser cutting machine nozzle abnormal or serious hot, check the internal lens immediately.

Use white paper to observe the red light, away from the nozzle or at an angle, if the red light has a significant shadow, inside the internal lens is dirt.

Use black photo paper to spot and observe whether there are shadows in the spot shape on the photo paper. If there are black spots, the lens is dirty.

The most direct judgment method is in the cleanroom with a microscope to observe the fiber output head, from the cutting head at both ends to observe whether there are internal anomalies.

After processing for a period of time there is not cut through

The main reasons are laser headlight path problem, laser power supply problem and cutting gas flow problem. When the focus temperature drifts or dirty, it will affect the laser energy to the surface of the material, and then can not cut through. At the same time, if the voltage of the power supply of the laser is unstable, the output power of the laser will be unstable, which will also lead to the inability to cut through, and if there is insufficient gas supply pressure or insufficient gas outlet problems caused by damaged nozzle will also cause incomplete cutting.

In the fiber laser machine processing, in order to effectively avoid the processing quality decline, should try to do the following points:

Choose the appropriate cutting process, avoid the limit of cutting speed batch processing sheet.

According to the thickness of the processing plate to choose the appropriate laser power, do not use the laser batch processing limit cutting capacity of the plate, such as the laser limit cutting thickness of 25 mm, then the laser batch processing thickness should be within 20 mm.

Choose a suitable water chiller to ensure that its flow and cooling capacity meets the requirements of the laser.

Design suitable cutting patterns for plates of different thicknesses. In principle, avoid processing patterns smaller than 0.8 times the plate thickness. In the case that the thickness of the plate is thick relative to the cutting ability of the laser, the sharp corners can be changed to round corners or pulsed cutting to avoid corner burning.

Reasonable arrangement of cutting order to avoid high-density cutting in the same area in a short time.

Improve the perforation process, avoid perforating instability caused by cutting lens dirt and nozzle damage.

Ensure fiber laser cutting machine uses the purity of the cutting gas and the stability of the output pressure.

Related Models: AF-1390 Series · AF-T Series

Please Share This

Get A Quick Quote Today!