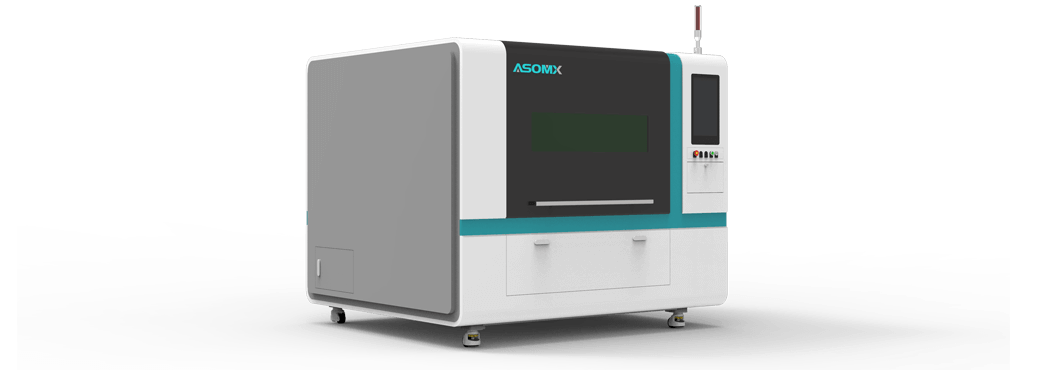

Features of Precision Laser Cutter

- Adopted carbon structural steel with good toughness, ductility, weldability and heat treatment properties. Excellent three-dimensional machine bed structure, strict heat treatment technology and precision processing level, ensure the high-performance machining equipment features.

- Auxiliary low gas pressure alarm function, provide real-time pressure detection, abnormal information report to ensure the laser cutting effect.

- Yaskawa servo motor and drive system, to provide customers with faster speed and better stability.

- Optical fiber transmission, no need to adjust the laser path. IPG and Raycus fiber sources are used as the laser resonator.

- The new security tracking module, in the cutting process, always maintains the distance between the laser head and the materials, reduce the risk of collision, to ensure cutting efficiency.

- Single-phase power supply can ensure the normal operation of the laser machine. This function makes it more convenient for the machine to connect the power supply and can work in various places.

- Imported rack and pinion, the most advanced grinding and tooth making process, with the highest precision of the same level material, suitable for high-speed movement and greatly reducing the driving horsepower required for the laser metal cutting machine.

- The pneumatic clamp is used to fix the cutting material to improve positioning accuracy. The blade distribution is automatically adjusted according to the two sides of the splint to prevent material leakage. Suitable for the thin plate, improve the machining precision.

- Automatically monitor the working range of crossbeam and cutting parts to keep them in the machining range. The double guarantee of fixed limitation greatly improves the equipment and personal safety and reduces the use of risk to the minimum.

- The operating system can realize the intelligent layout of graphics cutting, support multi-graphics input, automatically optimize the cutting order, intelligent edge search, automatic positioning.

- The new drawer-type worktable is convenient for loading and unloading, greatly reducing the machine floor area, effectively improve the space utilization.

- The automatic lubrication system provides the equipment with regular and quantitative lubricating oil to ensure the normal and high-speed operation of the laser cutter and has the function of abnormal alarm and liquid level alarm. The system greatly improves the cutting accuracy and effectively prolongs the service life of the transmission mechanism.

- All-around protection design, sealed operation space, completely shield smoke and laser radiation, minimize pollution and ensure safety.

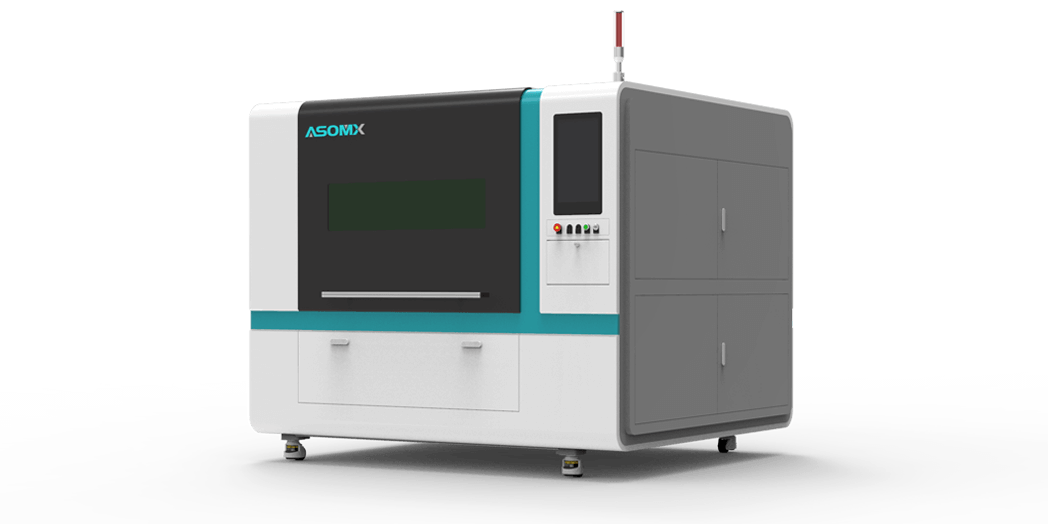

Product Details and Configuration

All the details and configuration can be customized according to your processing requirements

Protective glass

1 of 8Collecting drawer

2 of 8Open handle

3 of 8Display

4 of 8Control button

5 of 8Warning light

6 of 8Control cabinet

7 of 8Machine anchor

8 of 8Technical Parameters

| Model No. | AF-1390 Series |

|---|---|

| Laser Power | 1000W/1500W/2000W/3000W |

| Laser Wavelength | 1080±10nm |

| Laser Type | Single-Core Junction Semiconductor Module |

| Cutting Head | Swiss Raytools / German Precitec |

| Working Range | 1300mm*900mm |

| Optional Range | 600mm*600mm |

| Min. Line Width | ≤0.1mm |

| Worktable Max. Load | 250kg |

| Max. Acceleration | 0.8G |

| Max. Moving Speed | 80m/min |

| Control System | Cypcut System |

| Positioning Accuracy | ±0.01mm |

| Repeatability Accuracy | ±0.02mm |

| Cooling Type | Industrial Circulating Water Cooling |

| Graphic Format Supported | DST, PLT, BMP, DXF, DWG, AI, JPG, DXP, PGN, TIF, LAS, etc. |

| Compatible Software | CORELDRAW, PHOTOSHOP, AUTOCAD, ARTCUT, etc. |

| Electricity Supply | 110V/220V±10% 50/60Hz |

| Unit Power | 12kw/13.7kw/15.6kw/26kw |

| Auxiliary Gas | Compressed Air / Nitrogen / Oxygen |

| Operating Temperature | 0°C-45°C |

| Working Humidity | 45%-95% no condensed water |

| Laser Module Life | 100000hours |

| Gross Weight | 1500kg |

| Package Dimensions | 2160*2402*2234mm |

Delivering Precise and Consistent Cutting for Metal

Industrial-grade components give you faster motion, better accuracy and increased laser power

Unparalleled Cut Quality and Consistency

Industry-leading performance at an affordable price, ASOMX laser ensures accuracy and longevity with multiple power options

Laser Cutting Sample Gallery

Click on the image to enlarge

Contact Us

Get your free quote, expert advice today.