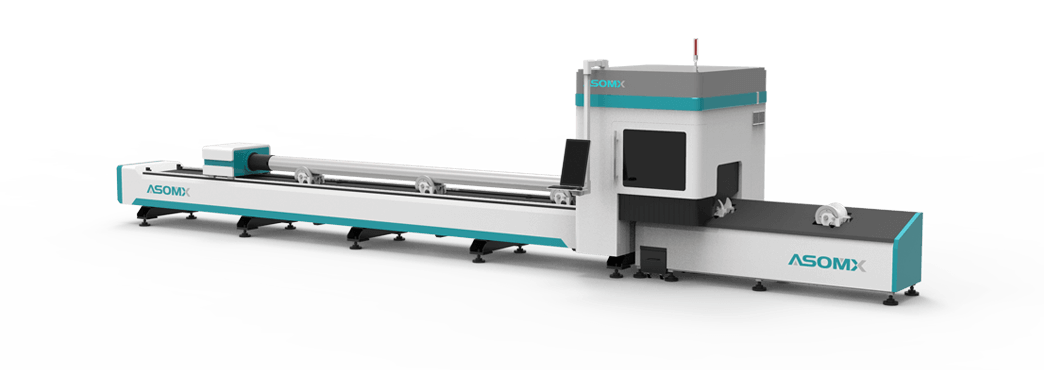

Features of Tube Laser Cutting Machine

- The mechanical structure uses the integrated gantry design, the performance is stable, the equipment runs smoothly.

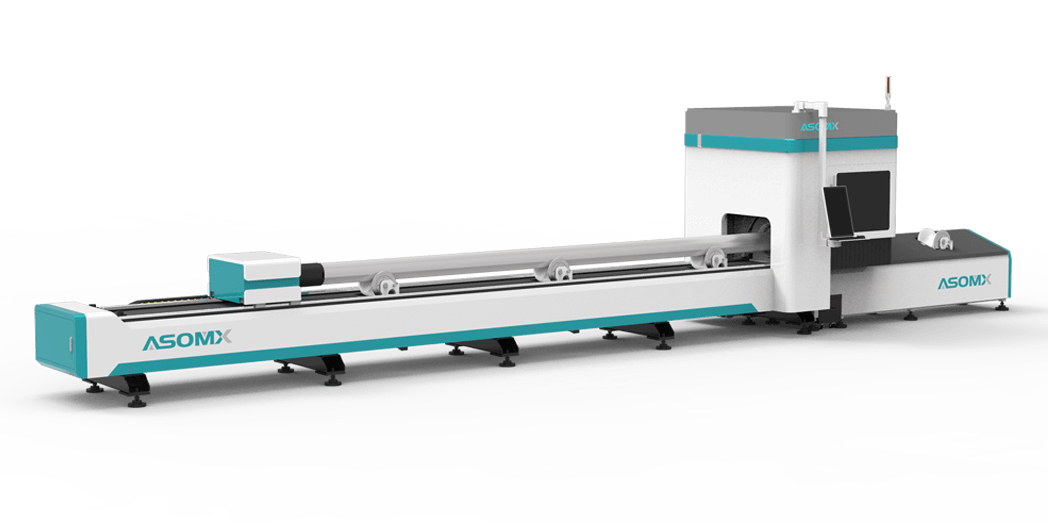

- Equipped with digital smart chuck, can realize the full-stroke pipe processing without manual adjustment. Intelligent system can easily identify and fix various types of pipes.

- Yaskawa servo motor and drive system to provide customers with faster speed and better stability.

- Optical fiber transmission, no need to adjust the laser path. IPG and Raycus fiber sources are used as the laser resonator.

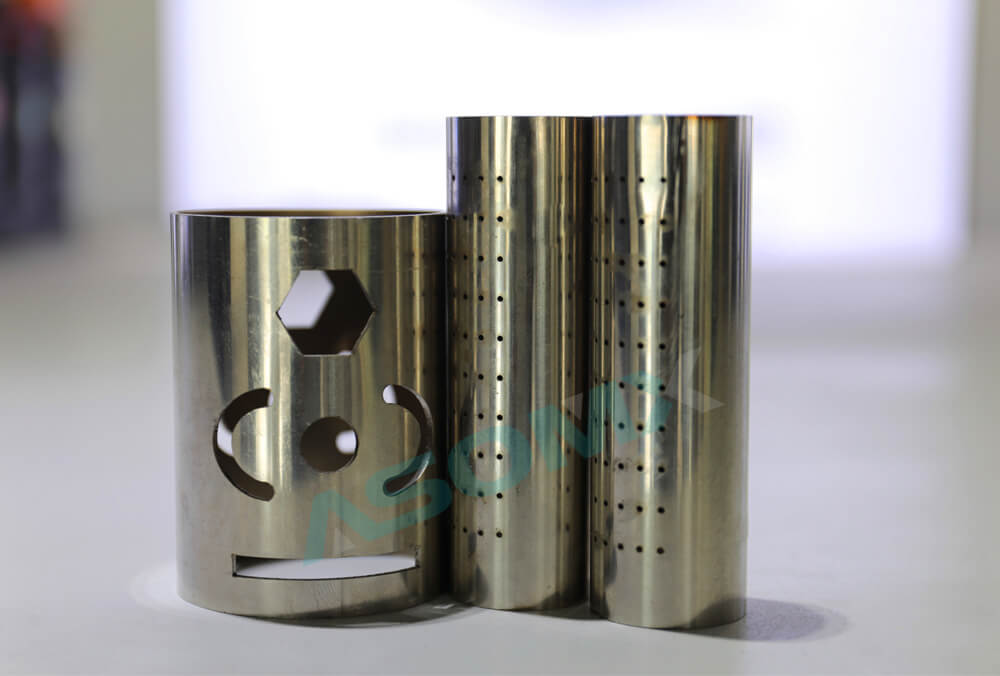

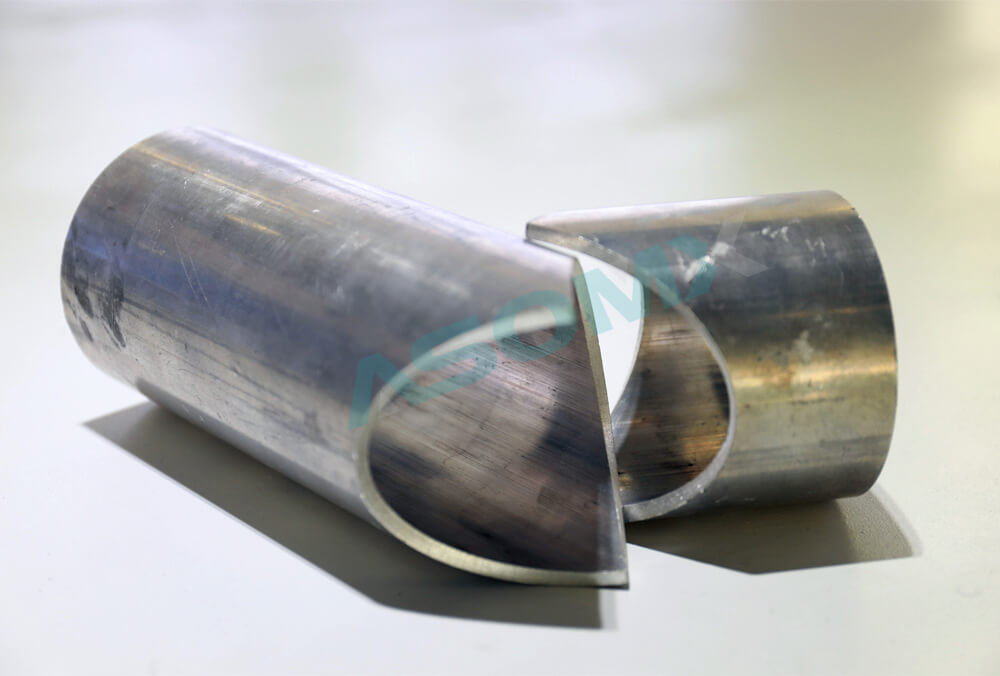

- Raytools and Precitec autofocus cutting head is controlled by the machine tool system, suitable for all kinds of focal length, in the cutting process, the focus is automatically adjusted to achieve the best cutting effect of different thickness pipes.

- Professional pressure feedback system can automatically adjust the pressure according to different diameters and thickness, real-time detection and alarm, high efficiency and safety.

- Imported rack and pinion, the most advanced grinding and tooth making process, with the highest precision of the same level material, suitable for high-speed movement and greatly reducing the driving horsepower required for the tube laser cutting machine.

- Automatic drift correction function, automatic center finding function, easy to operate, very intelligent and practical.

- Fully automatic pneumatic chuck can quickly align the workpiece, also through pressure adjustment to ensure the stability of the clamping force.

- Professional automatic nesting software, automatic one-key typesetting, no longer wastes customers' materials, provide igs format three-dimensional digital and analog graphics.

- Machine body uses standard square pipe, 600°C high-temperature heat treatment, 12 meters gantry milling finishing, 24-hour oven cooling, to ensure the precision and long-term use of the machine is not deformation.

- Four-edge search function, optimized edge search pattern and algorithm make the detection of pipe more accurate.

- Shortest travel path and the fastest movement speed by using the unique pipe database in the cutting software and the closed-loop feedback between the height controller and the laser head.

Product Details and Configuration

All the details and configuration can be customized according to your processing requirements

Pneumatic chuck

1 of 9Collecting drawer

2 of 9Display

3 of 9Tanks chain

4 of 9Back-up roller

5 of 9Pneumatic components

6 of 9Fire curtain

7 of 9Machine anchor

8 of 9Warning light

9 of 9Technical Parameters

| Model No. | AF-T Series |

|---|---|

| Laser Power | 1000W/1500W/2000W/3000W/4000W |

| Laser Wavelength | 1080±10nm |

| Laser Type | Single-Core Junction Semiconductor Module |

| Cutting Head | Swiss Raytools / German Precitec |

| Working Range | 6000mm |

| Optional Range | 12000mm |

| Min. Line Width | ≤0.1mm |

| Worktable Max. Load | 400kg |

| Max. Acceleration | 1.5G |

| Max. Moving Speed | 120m/min |

| Control System | TubePro System |

| Positioning Accuracy | ±0.01mm |

| Repeatability Accuracy | ±0.02mm |

| Cooling Type | Industrial Circulating Water Cooling |

| Graphic Format Supported | DST, PLT, BMP, DXF, DWG, AI, JPG, DXP, PGN, TIF, LAS, etc. |

| Compatible Software | CORELDRAW, PHOTOSHOP, AUTOCAD, ARTCUT, etc. |

| Electricity Supply | 220V/380V±10% 50/60Hz |

| Unit Power | 15kw/17kw/19kw/28kw/34kw |

| Auxiliary Gas | Compressed Air / Nitrogen / Oxygen |

| Operating Temperature | 0°C-45°C |

| Working Humidity | 45%-95% no condensed water |

| Laser Module Life | 100000hours |

| Gross Weight | 4750kg |

| Package Dimensions | 9740*2000*2520mm |

Delivering Precise and Consistent Cutting for Metal

Industrial-grade components give you faster motion, better accuracy and increased laser power

Unparalleled Cut Quality and Consistency

Industry-leading performance at an affordable price, ASOMX laser ensures accuracy and longevity with multiple power options

Contact Us

Get your free quote, expert advice today.