Stainless Steel and Carbon Steel Metal Plate Fiber Laser Cutting Common Problems and Solutions

When a CNC laser cutter cuts stainless steel and carbon steel, the metal is melted and vaporized when the laser beam hits the surface of the steel plate. Laser cutting of stainless steel and carbon steel sheet is a fast and effective method for sheet metal processing.

If the laser cutting process parameters are strictly controlled during the processing, the corrosion resistance of the material can be maintained. The main technological parameters affecting the cutting quality are cutting speed, laser power and air pressure. The specific problems and debugging methods are as follows:

Stainless Steel Laser Cutting

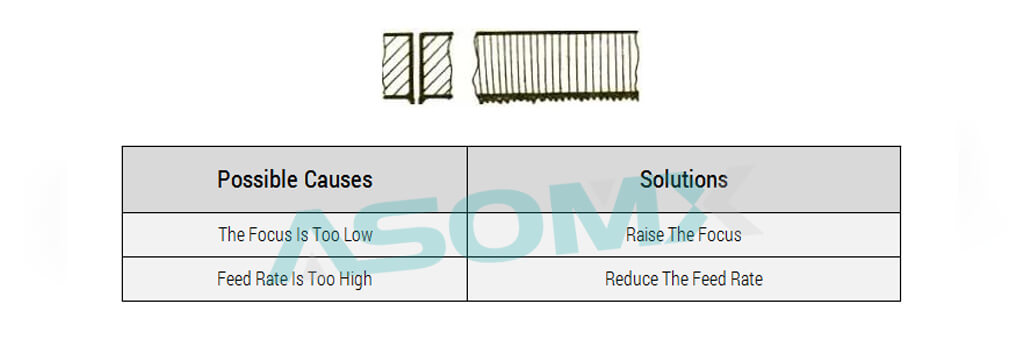

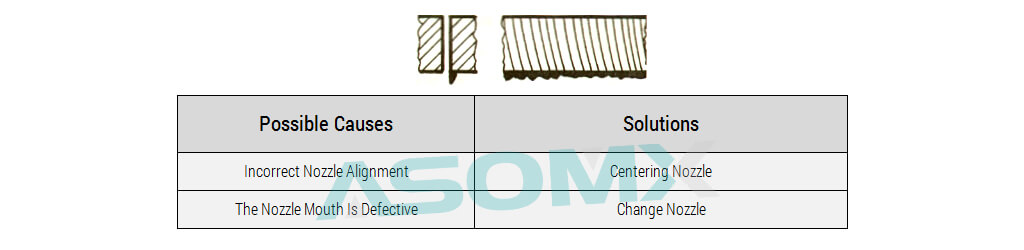

Producing Tiny Regular Burrs In The Shape of Drops

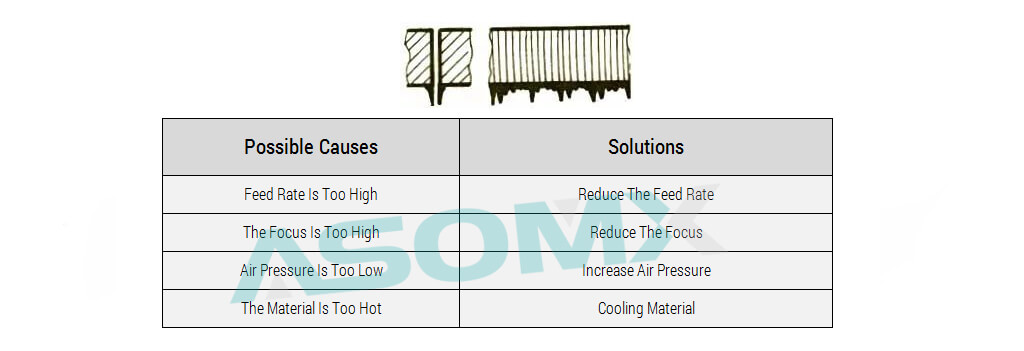

Long Irregular Burrs on Both Sides and Discoloration of The Plate Surface

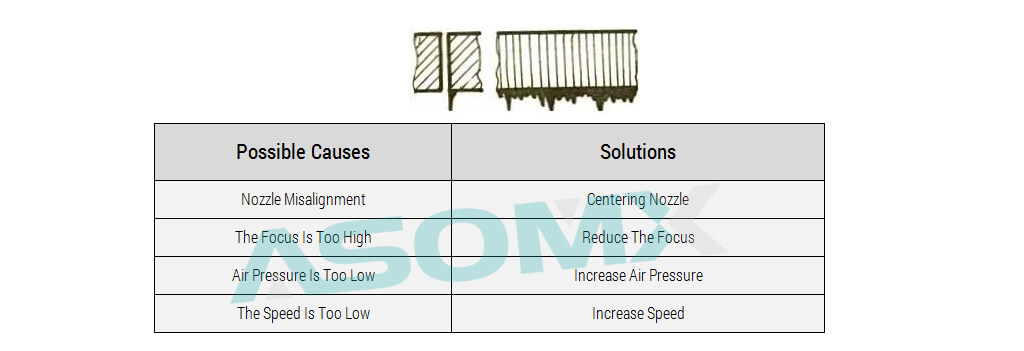

Produces Long and Irregular Burrs on Only One Side of The Cut Seam

Material Is Discharged From Above

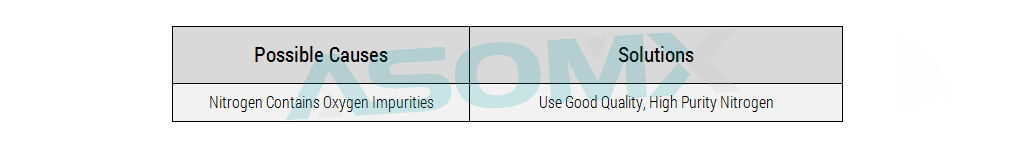

The Cutting Seam Is Yellow

Carbon Steel Laser Cutting

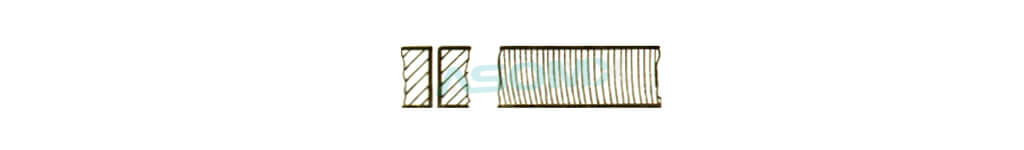

Under normal cutting conditions, the fiber laser cutter process the carbon steel should be burr-free and the drawing lines should be uniform, as shown in the following figure.

However, due to improper debugging, there may be some cutting problems, should be adjusted according to the cutting results.

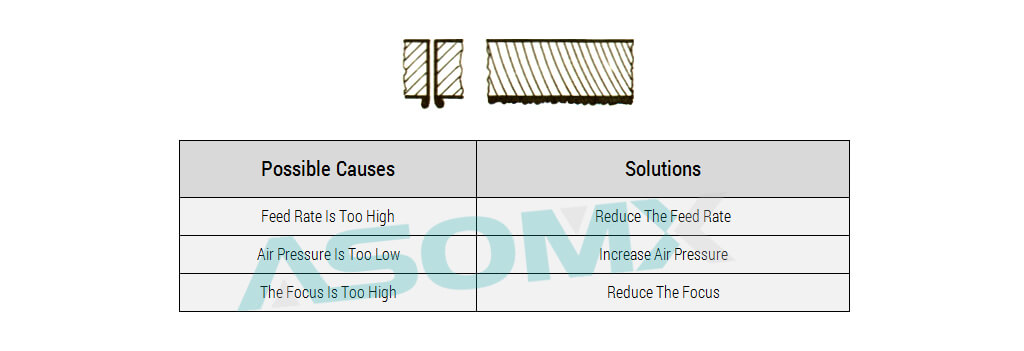

The Lower Traction Line Offset Is Large and The Lower Incision Is Wide

Burrs on The Bottom Surface are Similar To Slag, Easy To Drop and Remove

The Joined Metal Burrs Can Be Removed as a Whole

The Metal Burr On The Bottom Surface Is Difficult To Remove

There are Only Burrs On One Side of The Cutting Plate

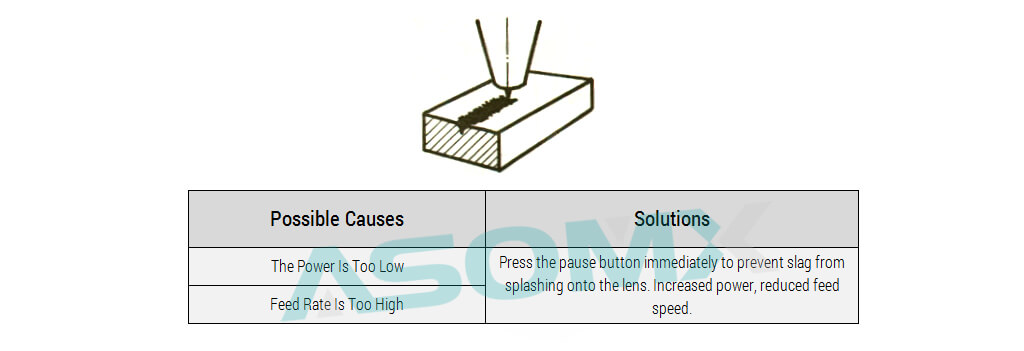

Material Is Discharged From Above

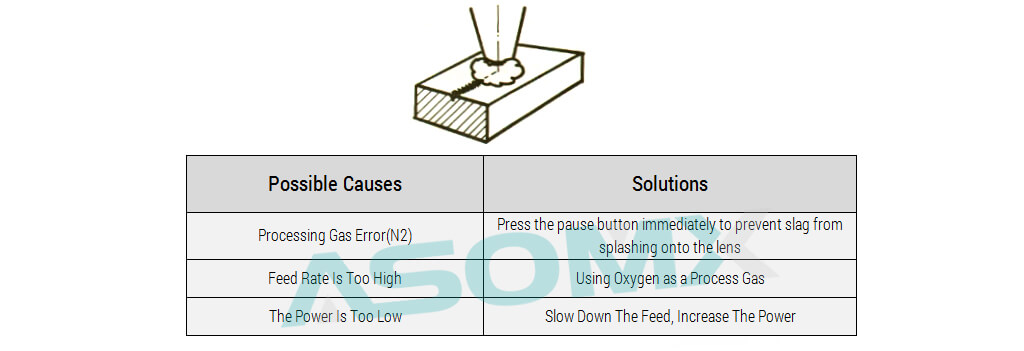

The Workpiece Is Not Cut Through

The Cutting Surface Is Imprecise

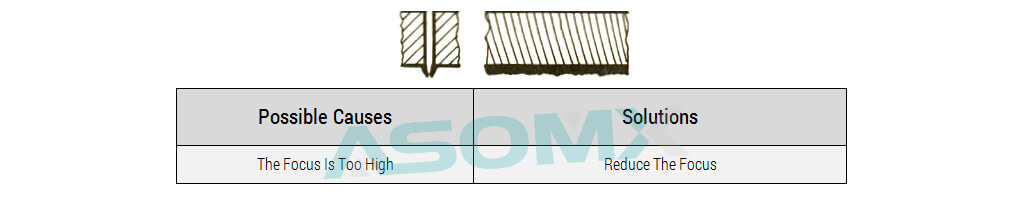

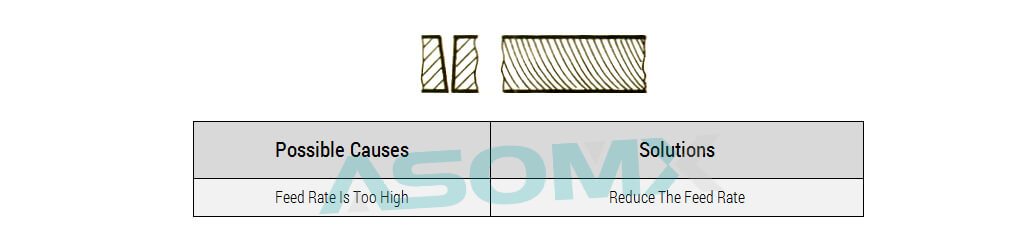

No Burrs, Traction Lines are Slanted and The Gap at The Bottom Is Narrow

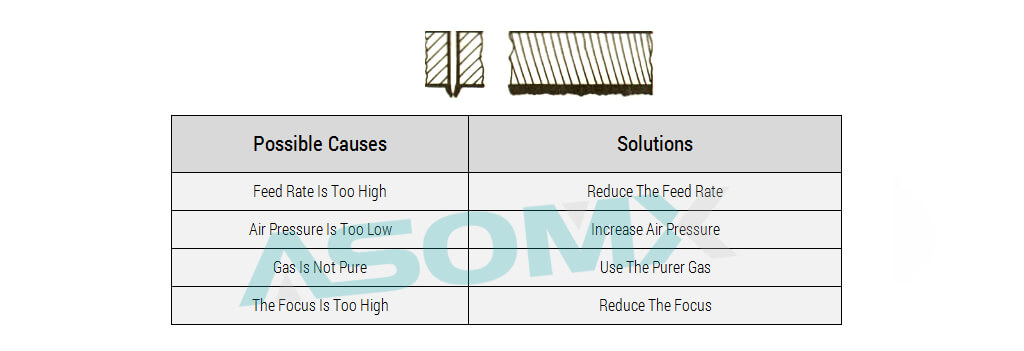

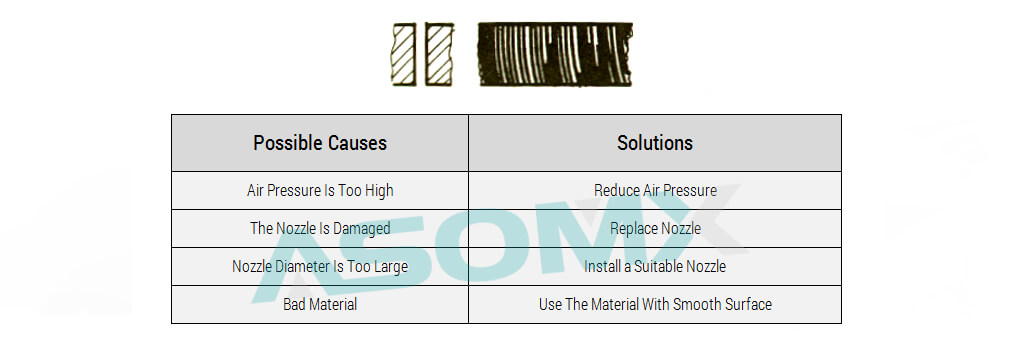

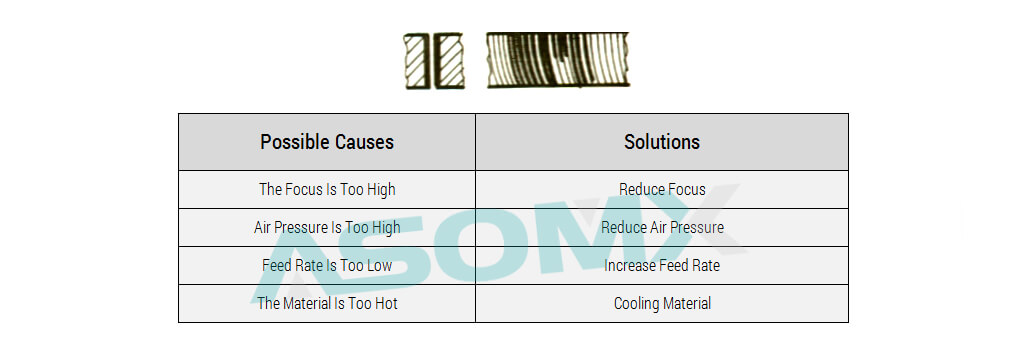

The Cutting Surface Is Very Rough

Related Models: AF-T Series · AF-N Series

Video Reference

Please Share This

Get A Quick Quote Today!