Selection of Gas Type and Blowing Mode In The Laser Welding Machine

Selecting the best welding shielding gas is the way to improve the welding quality and efficiency. In laser welding, shielding gas will affect the weld shape, weld quality, penetration depth and weld width. In most cases, the blowing of shielding gas will have a positive effect on the weld and may also have a negative effect.

Positive Effect of Shielding Gas In Laser Welding

Proper blowing of protective gas can effectively protect the welding pool from oxidation.

Proper blowing of protective gas can effectively reduce the spatter in the welding process.

Proper blowing of protective gas can promote uniform expansion of the molten pool during solidification process and make weld formation uniform and beautiful.

Proper blowing can effectively reduce the shielding effect of metal vapor plume or plasma cloud on laser, and improve the effective utilization ratio of laser.

Proper blowing of shielding gas can effectively reduce weld porosity.

Influence of Improper Use of Shielding Gas In Laser Welding

The wrong type of gas may lead to the crack of the weld and decrease the mechanical properties of the weld.

The wrong gas flow rate may lead to the oxidation of the weld and the disturbance of the weld pool metal by the external force, which may cause the weld to collapse or form unevenly.

Improper selection of blowing method may lead to the weld can not achieve the protective effect or have a negative impact on the weld formation.

Improper injection of shielding gas will affect the weld penetration, especially in thin plate welding, it will reduce the weld penetration.

Type of Protective Gas In Laser Welding

Nitrogen

Argon

Helium

The Blowing Method of Shielding Gas

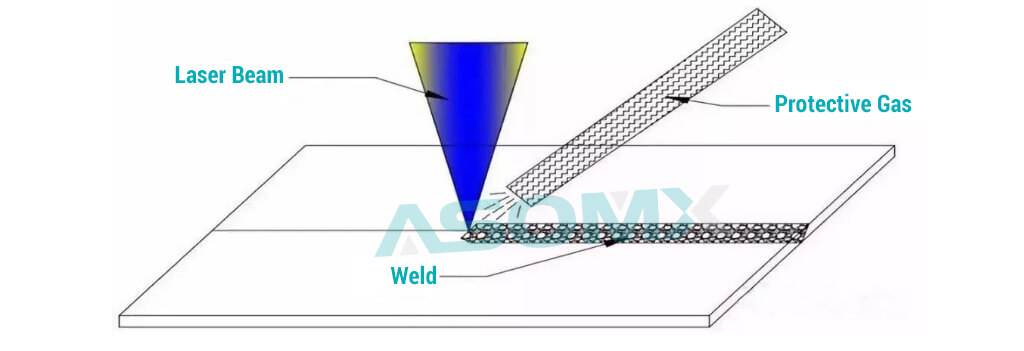

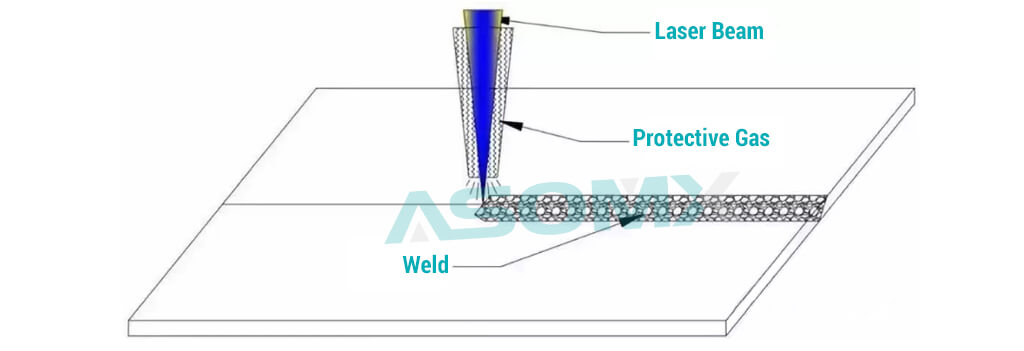

There are two main methods of blowing protection gas: one is as shown on the left figure below side blowing shielding gas, and the other is as shown in the right figure below coaxial protection gas.

The blowing of shielding gas requires not only the timely protection of the weld pool but also the protection of the newly solidified zone after welding. Therefore, the side blowing protection gas shown in the left figure is generally used. The protection range of this method is wider than that of the coaxial protection shown in the right figure.

As far as engineering applications are concerned, not all products can be protected by side blowing. For some specific products, only coaxial protection gas can be used, which requires a specific choice from the product structure and joint form.

Selection of Specific Protective Gas Blowing Method

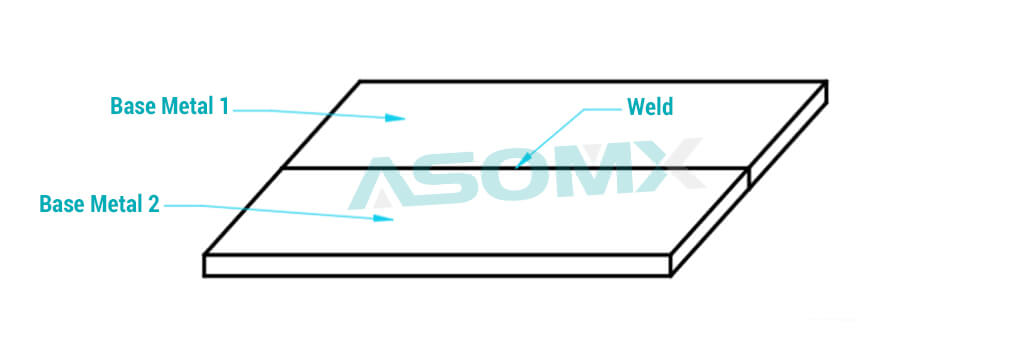

Straight Weld: As shown in the following figure, the product weld shape is a straight line, the joint form has butt joints, lap joints, internal corner joints or overlap welded joints. This product is the preferred product for the use of side-blown protective gases.

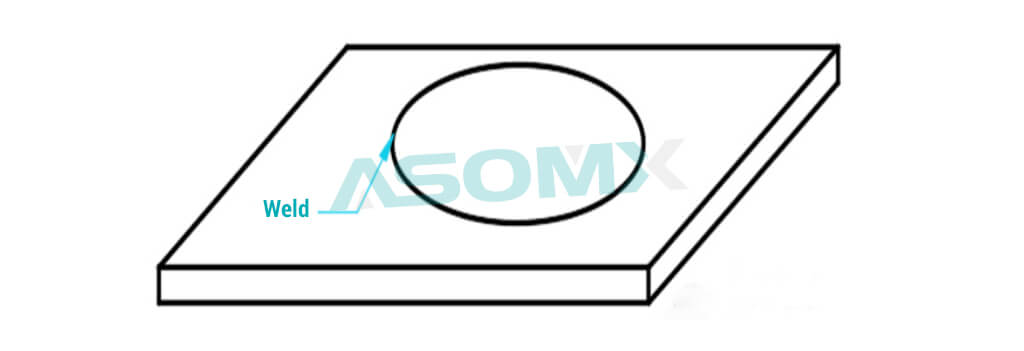

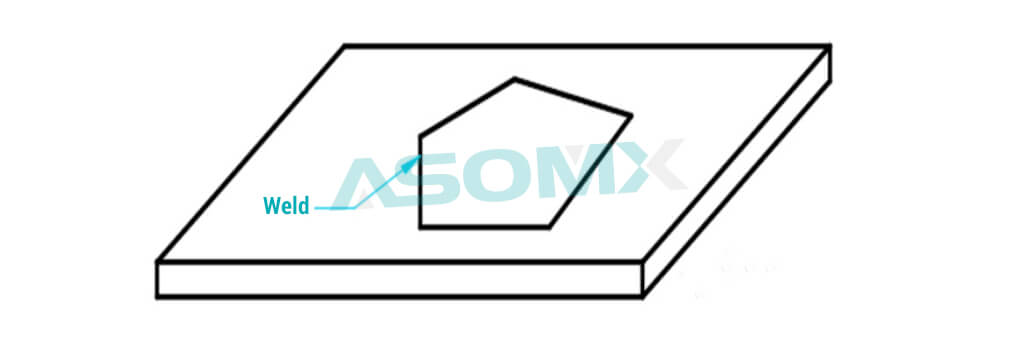

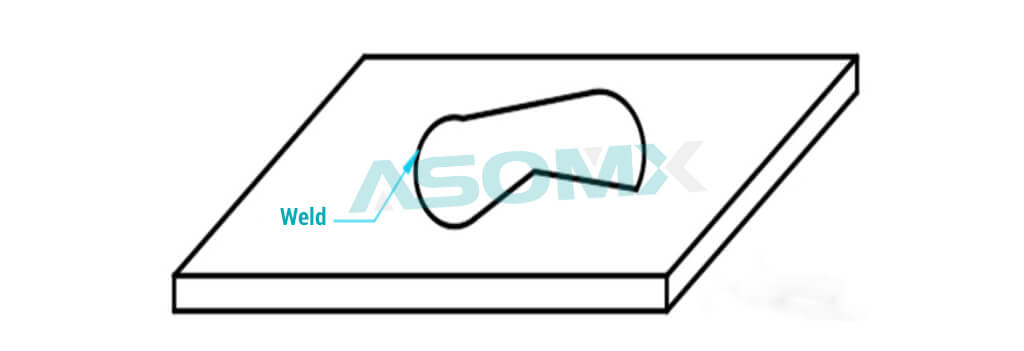

2D Closed Shape Weld: As shown in the following figure, the product’s weld shape for the plane circumferential shape, plane polygonal shape, plane multi-segment linear and other closed graphics. The joint forms are butt joint, lap joint and lap welding joint. Coaxial shielding gases are preferred for this type of product.

The selection of shielding gas directly affects the quality, efficiency and cost of welding production. However, due to the diversity of welding materials, the selection of welding gas in the actual welding process is also complicated, which requires comprehensive consideration of welding materials, welding method, welding position and welding effect. Through the welding test, the most suitable welding gas can be selected to achieve the best welding effect.

Related Models: AW Series

Video Reference

Please Share This

Get A Quick Quote Today!