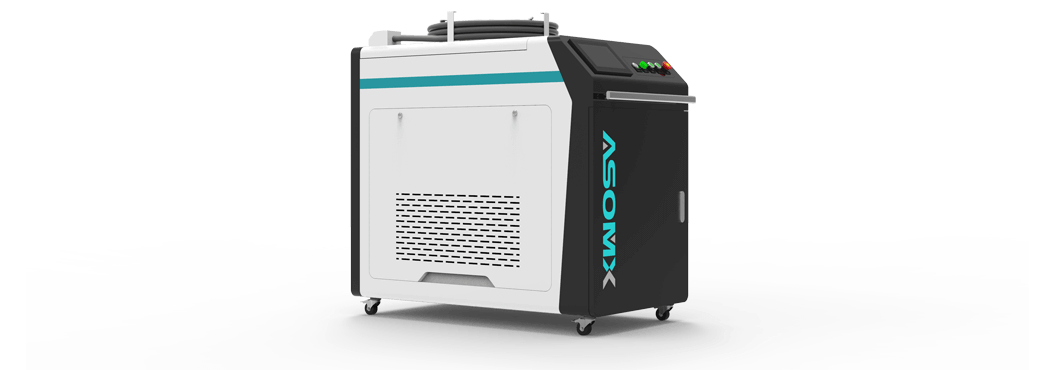

Features of Handheld Laser Welder

- Compared with the traditional welding equipment, the handheld laser welder speed is more than 2 times of the solid YAG laser welding speed, 3-5 times of the ARC welding speed.

- Photoelectric conversion efficiency is more than 30%, while solid YAG laser conversion efficiency is only 3%, low energy consumption, reduce production and processing unnecessary costs.

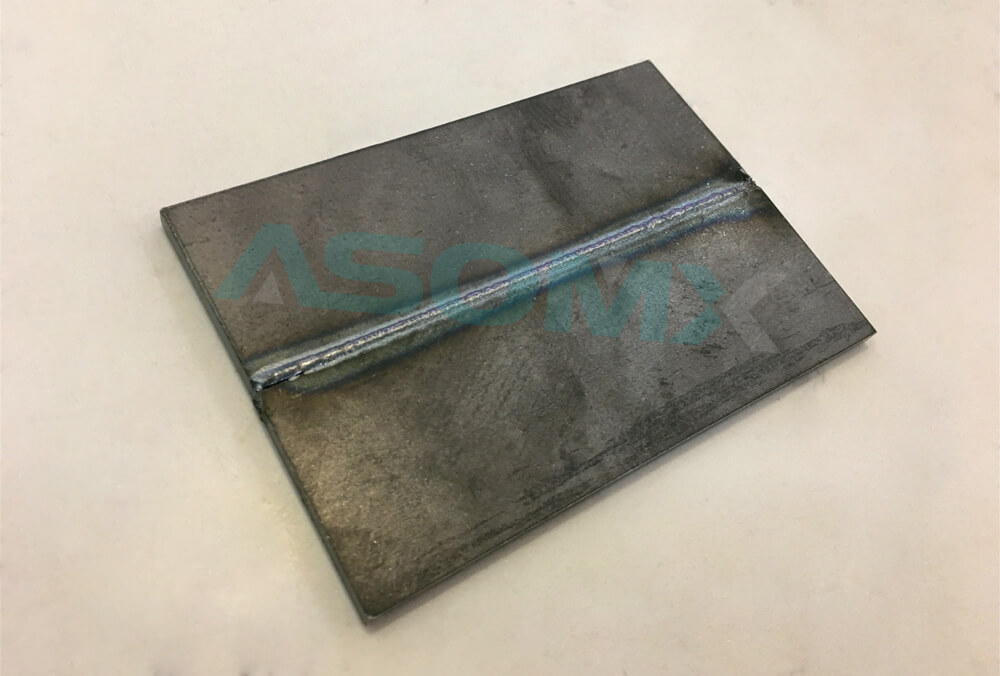

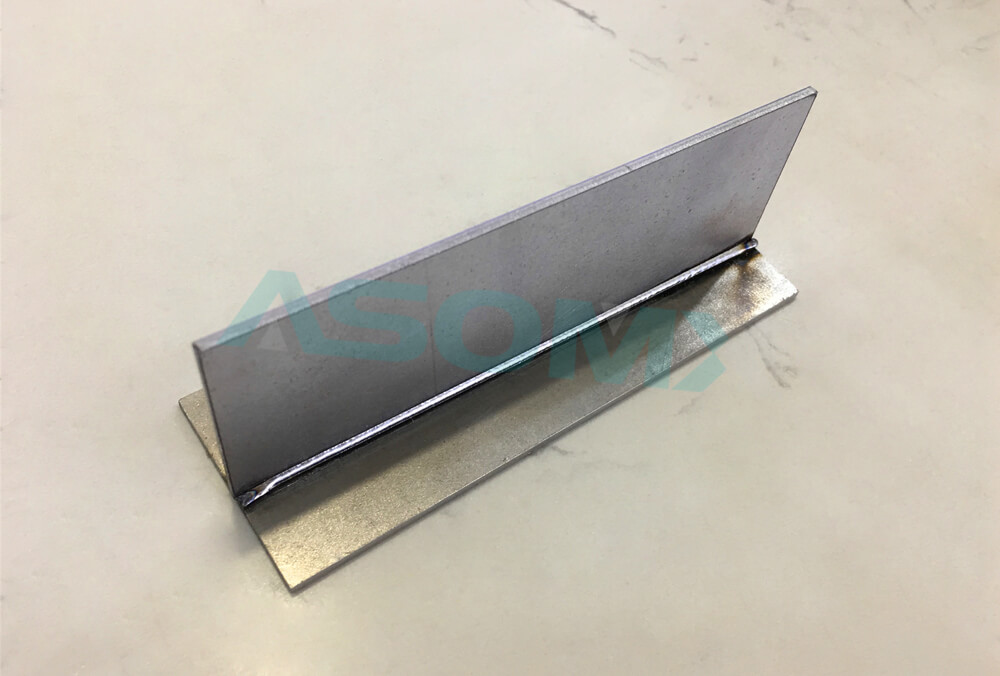

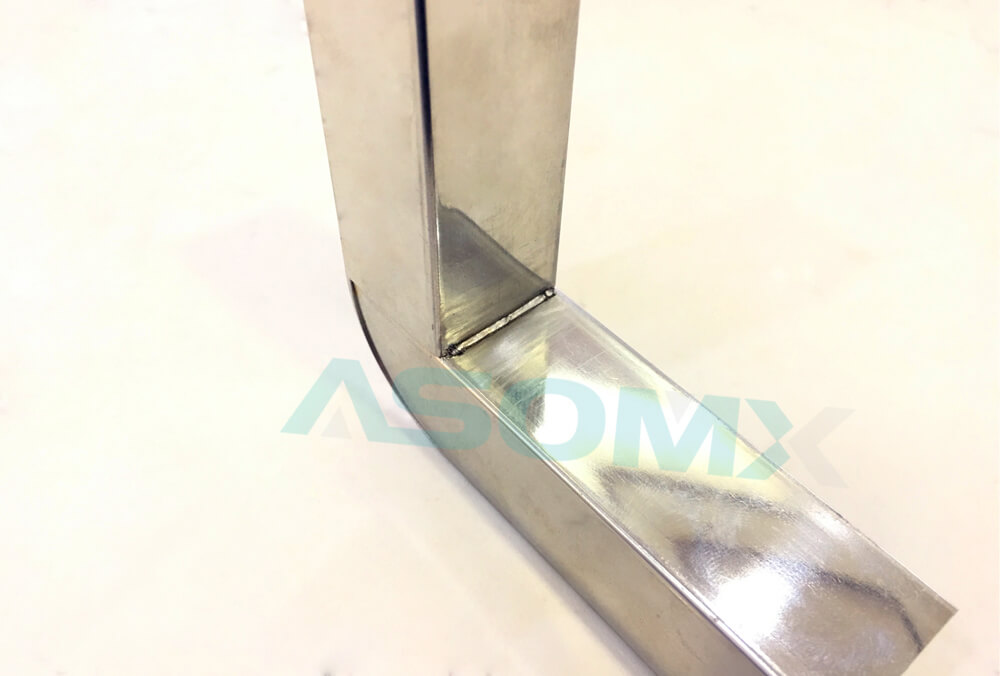

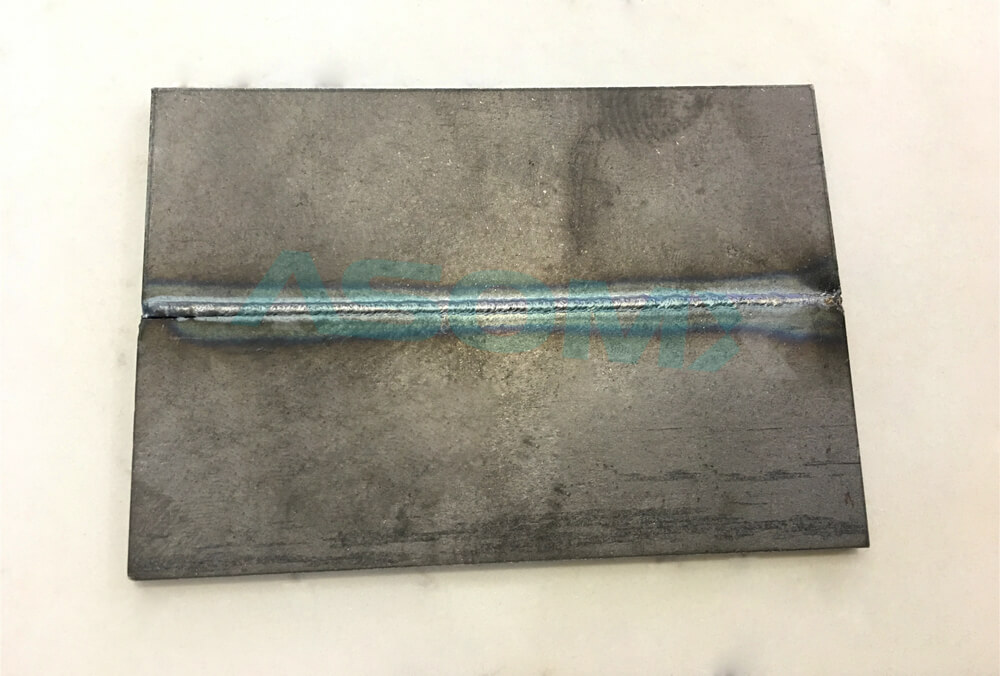

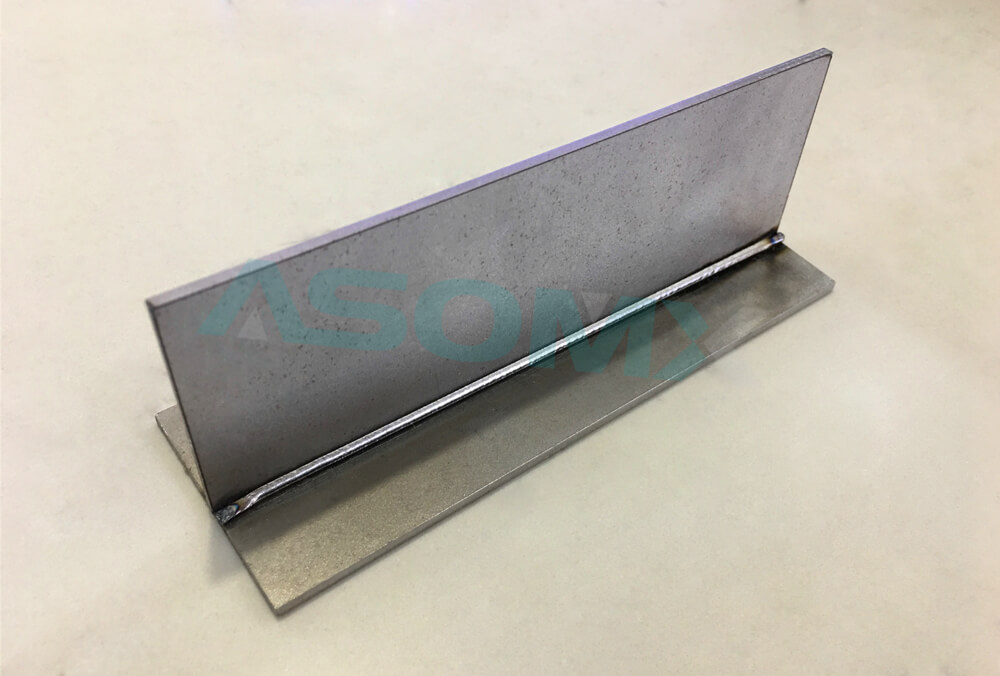

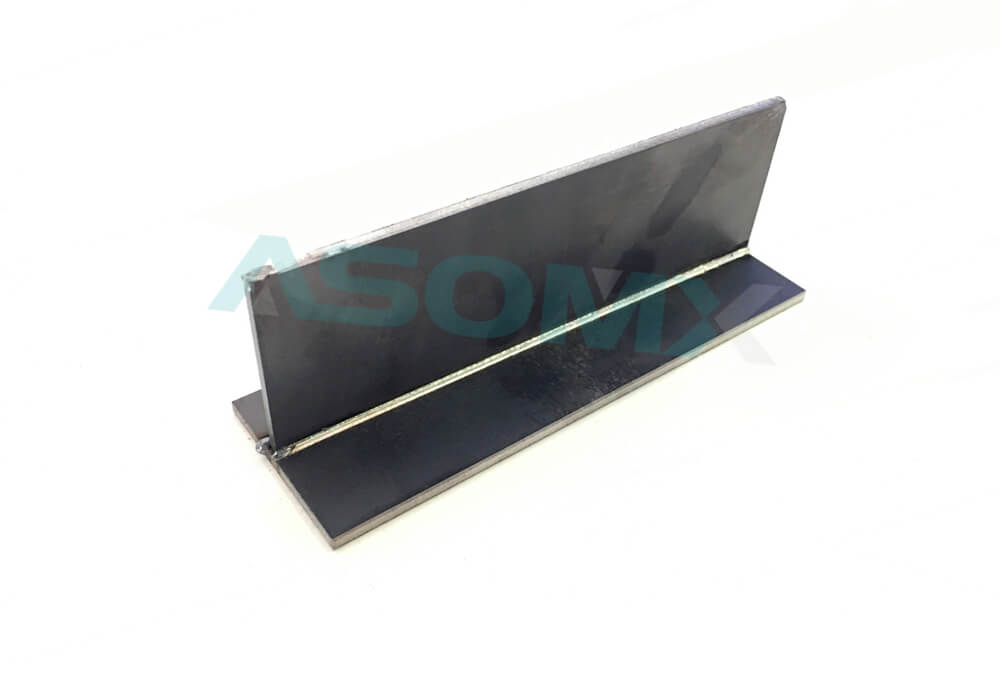

- No raised welding spot on the welding surface, no need for polishing and grinding process, save working time, beautiful appearance.

- 5-meter-long imported optical fiber connection laser head, which can be used for long-distance welding of products that are large and difficult to move.

- High energy density, low heat input, small thermal deformation, narrow melting zone and heat-affected zone.

- Compared with the contact welding, the laser welding does not need the electrode, reduces the daily maintenance cost, greatly improves the work efficiency.

- Fiber laser welding machine can be customized special automatic fixture to achieve batch production of products.

- Laser welding machine head can be equipped with a variety of angle nozzles to meet the welding needs of different products.

- The intelligent internal design and interactive control system expand the tolerance range and the weld width of the processing parts solves the defect of a small laser welding spot and provides better welding forming.

- Multiple security alarms, which automatically lock the light after removing the workpiece.

- Imported ceramic condenser cavity, corrosion resistance, high-temperature resistance, long service life.

- The laser welding of difficult parts adopts the non-contact method, and the welding method is more flexible. The laser beam realizes the separation of time and energy, and the multi-beam processing makes the welding more precise.

- One of the great conveniences of this portable laser welder is the internal water chiller. This chiller is a constant temperature industrial model, greatly saving the size of the machine.

Product Details and Configuration

All the details and configuration can be customized according to your processing requirements

Thermal design

1 of 7Optic cable

2 of 7Display

3 of 7Control button

4 of 7Push handle

5 of 7Control cabinet

6 of 7Movable wheel

7 of 7Technical Parameters

| Model No. | AW Series |

|---|---|

| Laser Power | 1000W/1500W/2000W |

| Laser Wavelength | 1080±5nm |

| Laser Type | Single-Core Junction Semiconductor Module |

| Welding Head | Xinghong / Qilin / WSX |

| Optic Length | 8000mm |

| Optional Length | 10000mm |

| Optical Fiber Interface | QBH |

| Pulse Frequency | 5~20KHz |

| Fiber Diameter | 50μm/100μm |

| Spot Size | Φ0.2-5mm adjustable |

| Welding Depth | 0.2-3mm |

| Output Power Tunability | 10-100% |

| Repeat Precision | ±0.01mm |

| Cooling Type | Industrial Circulating Water Cooling |

| Beam Quality | M2<1.1 |

| Power Stability | ±2% |

| Electricity Supply | 220V/380V±10% 50/60Hz |

| Unit Power | 7.5kw/8.5kw/10kw |

| Auxiliary Gas | Nitrogen, Argon and other inert gases |

| Operating Temperature | 0°C-45°C |

| Relative Humidity | ≤70% |

| Laser Module Life | 100000hours |

| Gross Weight | 200kg |

| Package Dimensions | 625*1756*1240mm |

Intelligent Internal Design and Interactive Control System

Overcome the traditional defects and save the maintenance cost

Breakthrough the limitation of worktable and save space cost

Small size, free up more space, reduce the equipment cost of occupying the workshop space

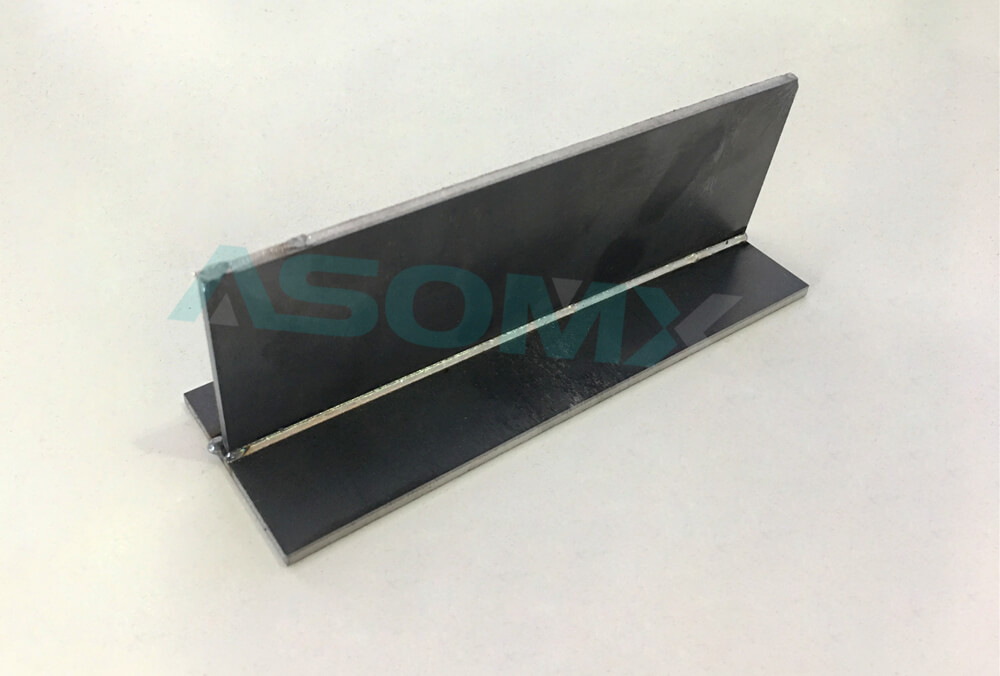

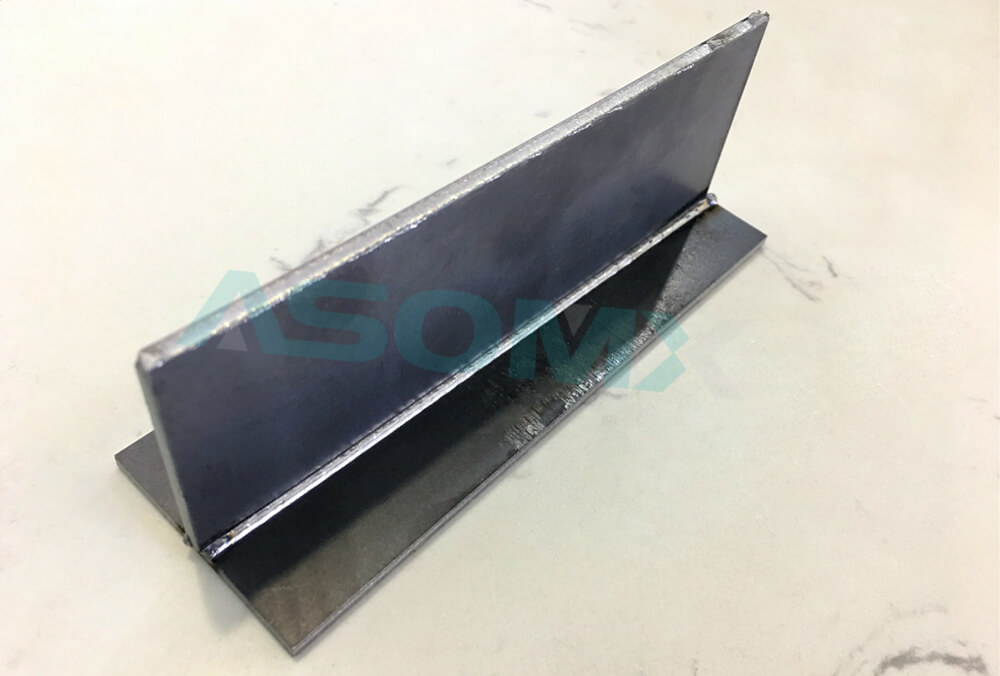

Laser Welding Sample Gallery

Click on the image to enlarge

Contact Us

Get your free quote, expert advice today.