Relationship Between Cutting Speed and Cutting Quality of High Power Fiber Laser Cutter

Laser power will affect the speed of the CNC laser machine equipment cutting sheet, and the speed of the laser equipment cutting sheet will affect the quality of laser cutting. Under certain laser power conditions, there is an optimum cutting speed range. If the speed is too fast or too slow, will affect the surface roughness of the cutting materials.

Cutting Speed Is Too Fast

1. The laser beam and the material contact in a short time may cause can not cut and produces the spark.

2. Some areas of the material can be cut, but some of it can’t.

3. The entire cutting section is delaminated.

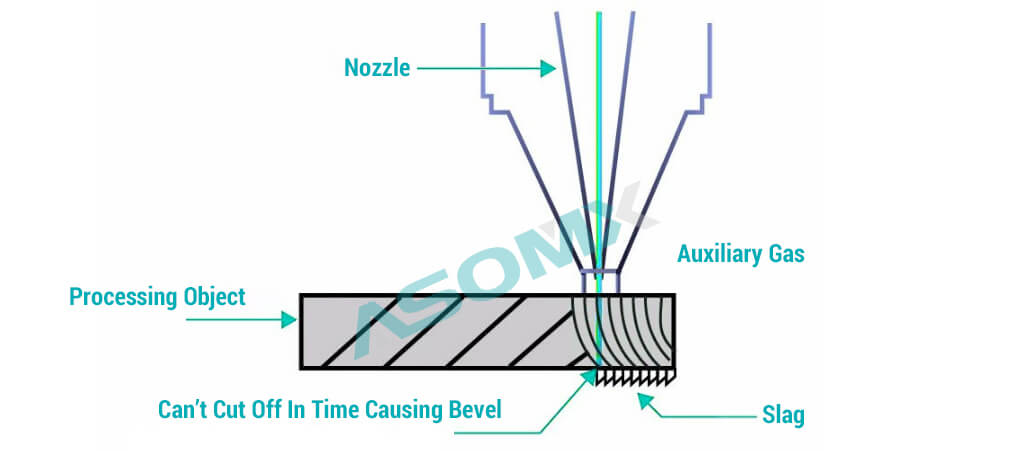

4. The material can not be cut in time. The cut section shows a diagonal stripe path and produces melted stains on the lower part of the plate.

Cutting Speed Is Too Slow

1. When the interaction time between the cutting material and the laser beam increases, the cutting plate will be over-melted and the cutting section will be rough.

2. The cutting seam is correspondingly widened, resulting in a smaller round corner or sharp corner burning, unable to obtain an ideal cutting effect.

3. Low cutting efficiency, affecting the production capacity.

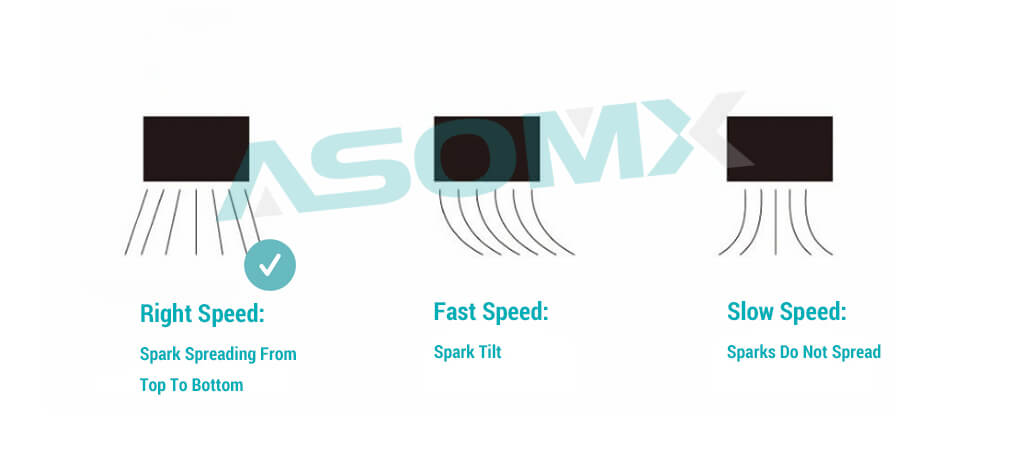

Judging Method of Cutting Speed

1. Right Cutting Speed: Cutting sparks from the top-down diffusion, cutting surface smooth, no slag at the bottom.

2. Cutting Speed Is Too Fast: The cutting spark is tilted.

3. Cutting Speed Is Too Slow: Cutting spark non-diffused, few, condensed together.

Related Models: AF-P Series · AF-G Series

Video Reference

Please Share This

Get A Quick Quote Today!