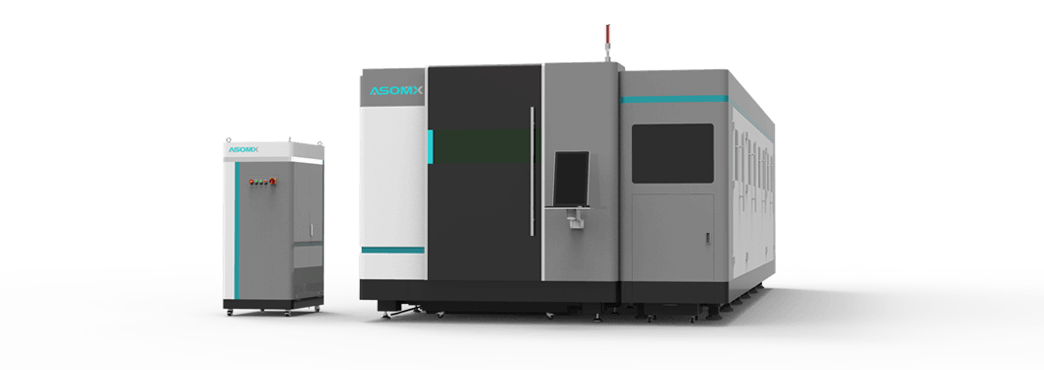

Features of Fully Enclosed CNC Laser Cutter

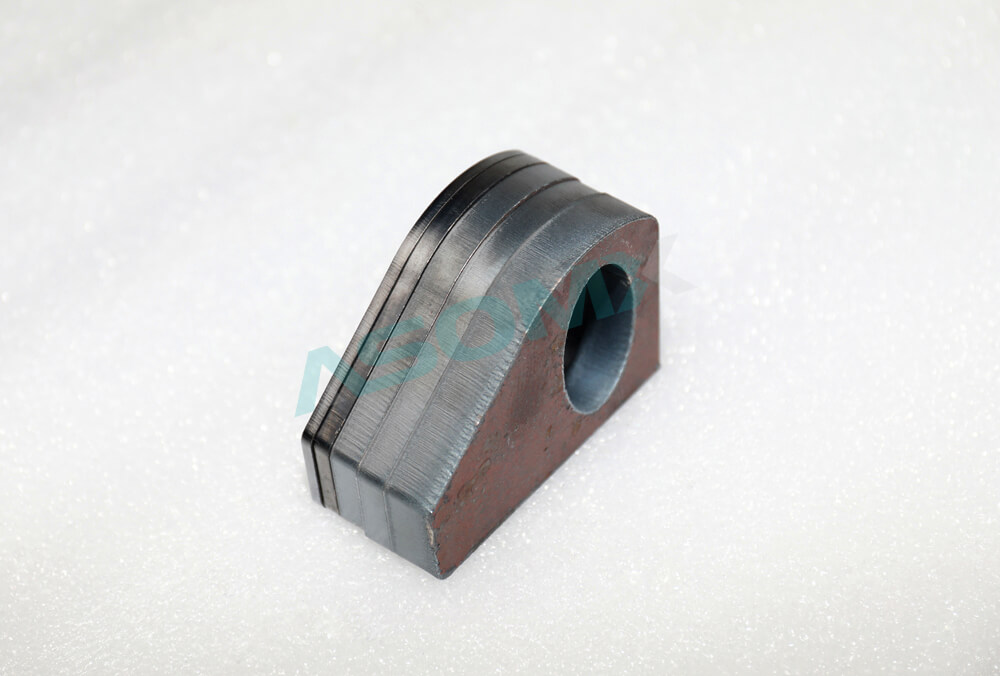

- 600 degrees heat treatment, cooling in the furnace for 24 hours, after the completion of annealing treatment, the use of gantry milling processing to improve accuracy.

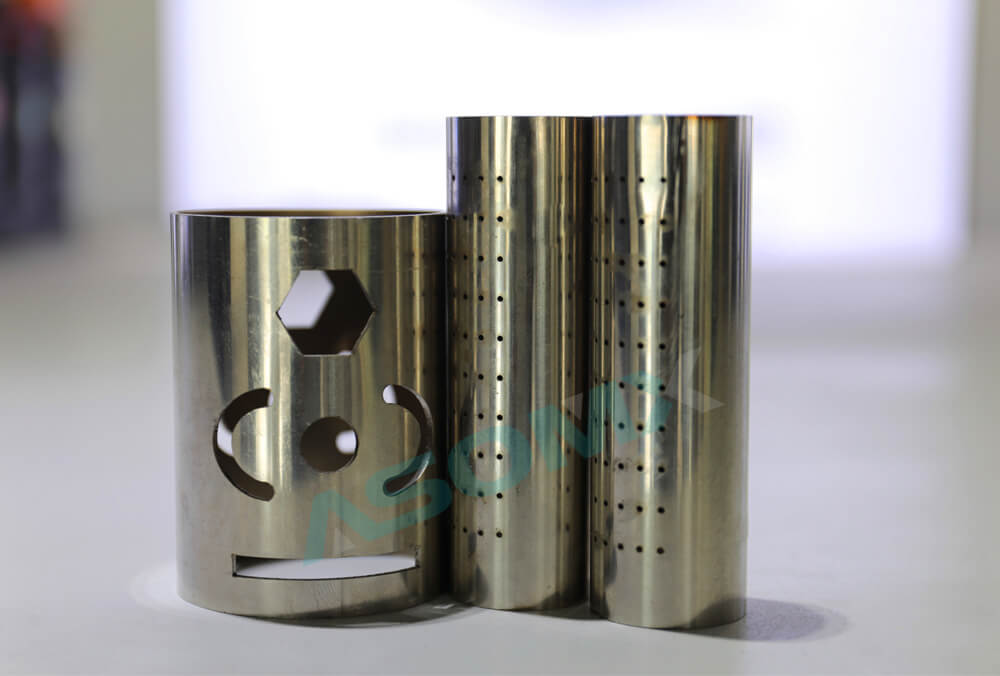

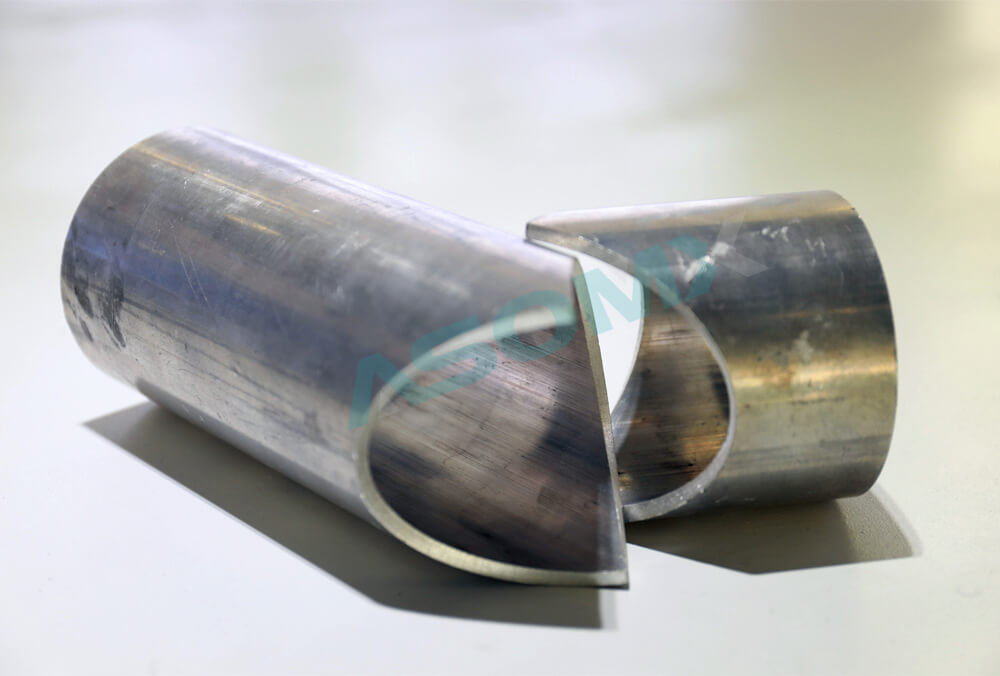

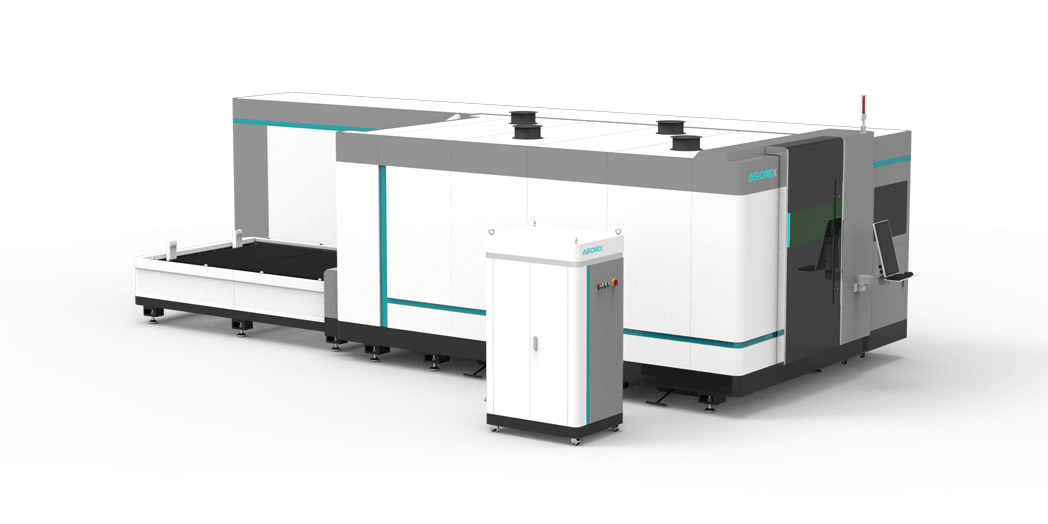

- The laser cutter combines the use of sheet metal cutting with pipe cutting, the enclosed cover is designed to effectively protect the operators.

- Japan Yaskawa servo motor and drive system, to provide customers with faster speed and better stability.

- Optical fiber transmission, no need to adjust the laser path. IPG and Raycus fiber sources are used as the laser resonator.

- Swiss Raytools and German PRECITEC autofocus cutting head is controlled by the system, automatically adjust the focal length according to the thickness of the plate, which can read system storage parameters automatically and save time and manpower.

- Heavy-duty gantry structure to ensure the stability of machine operation, with good impact resistance and wear resistance. Low thermal sensitivity, bed gap sensitivity, reduce the loss of equipment in the use process, so that machining accuracy can be maintained for a long time, does not deform during the life cycle.

- Imported high-precision gear and rack drive system ensure high-speed, high-precision and good dynamic characteristics. The drive structure with two synchronous servo motors balances the pressure and long service life.

- Dual worktables reduce loading and unloading time. Adopting the rotating ball rack on the worktable to make it more convenient to move the workpiece. The positioning device and the fixture can position the plate to ensure the movement of the plate and the processing accuracy.

- Aluminum alloy has the characteristics of lightweight and strong rigidity, which is good for high-speed movement in machining, and high flexibility is good for high-speed cutting based on high precision. The light beam can improve the running speed of the equipment, improve the processing efficiency and ensure the processing quality.

- Import automatic programming, automatic translation of CAD drawings into CNC language, automatic layout, saving materials, improve production efficiency.

- Adopt imported pneumatic components to ensure the laser machine running normally and without error. All kinds of gas automatically transition to meet different purposes of cutting a variety of materials and thick plates. Convenient, accurate, to ensure smooth, high-speed and clean cutting.

- Laser cutter has a perfect cooling system, lubrication system and dust removal system to ensure stable, efficient and lasting machine operation.

- Unique tube plate up and down, front and back centering device to ensure that the material is placed in the center of the chuck when feeding.

Product Details and Configuration

All the details and configuration can be customized according to your processing requirements

Display

1 of 9Switching platform

2 of 9Fully enclosed cover

3 of 9Control buttons

4 of 9Positive pressure fan

5 of 9Control cabinet

6 of 9Laser protective glass

7 of 9Warning light

8 of 9Monitor

9 of 9Technical Parameters

| Model No. | AF-G Series |

|---|---|

| Laser Power | 1000W - 12000W |

| Laser Wavelength | 1080±10nm |

| Laser Type | Single-Core Junction Semiconductor Module |

| Cutting Head | Swiss Raytools / German Precitec |

| Working Range | 1500mm*3000mm |

| Optional Range | 2000mm*4000mm / 2000mm*6000mm |

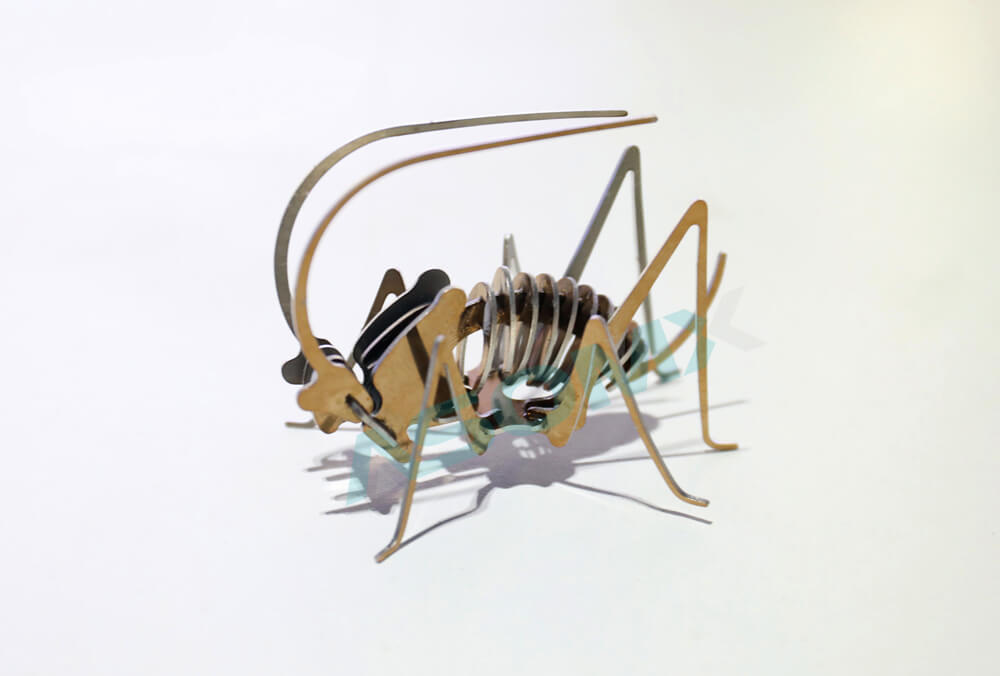

| Min. Line Width | ≤0.1mm |

| Worktable Max. Load | 1600kg |

| Max. Acceleration | 1.5G |

| Max. Moving Speed | 120m/min |

| Control System | Cypcut System / Cyptube System |

| Positioning Accuracy | ±0.01mm |

| Repeatability Accuracy | ±0.02mm |

| Cooling Type | Industrial Circulating Water Cooling |

| Graphic Format Supported | DST, PLT, BMP, DXF, DWG, AI, JPG, DXP, PGN, TIF, LAS, etc. |

| Compatible Software | CORELDRAW, PHOTOSHOP, AUTOCAD, ARTCUT, etc. |

| Electricity Supply | 220V/380V±10% 50/60Hz |

| Unit Power | 19.3kw/21.8kw/26.5kw/29.6kw/33.4kw/41.4kw/52kw |

| Auxiliary Gas | Compressed Air / Nitrogen / Oxygen |

| Operating Temperature | 0°C-45°C |

| Working Humidity | 45%-95% no condensed water |

| Laser Module Life | 100000hours |

| Gross Weight | 8800kg |

| Package Dimensions | 8220*4750*2170mm |

Delivering Precise and Consistent Cutting for Metal

Industrial-grade components give you faster motion, better accuracy and increased laser power

Unparalleled Cut Quality and Consistency

Industry-leading performance at an affordable price, ASOMX laser ensures accuracy and longevity with multiple power options

Contact Us

Get your free quote, expert advice today.