How To Set The Right Focus Position Of CNC Laser Cutter In The Process Of Laser Metal Cutting

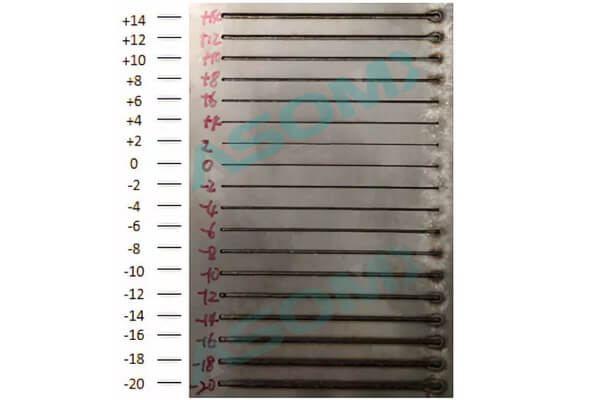

Distance from the focus to the upper surface of the machined workpiece called focus position. The position of the focus above the workpiece is generally referred to as the positive focus, and the position of the focus below the workpiece is generally referred to as the negative focus.

The Meaning of Focus Position

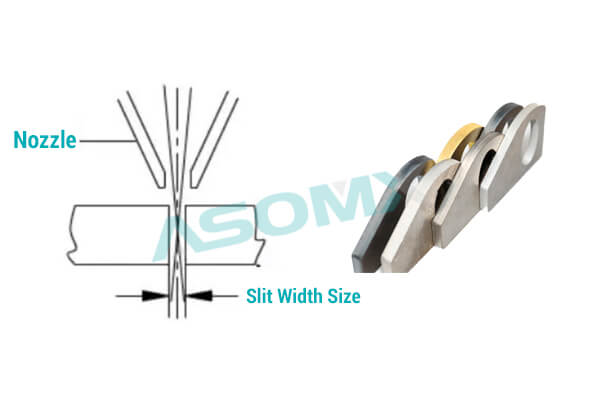

Changing the focus position means changing the spot size on the surface and inside of the plate. The focusing length increases, the light spot thickens and the slit widens, which affects the heating area, the slit size and the slag removal ability.

Positive Focus Cutting

The focus is located above the cutting material.

For oxygen cutting of carbon steel, positive focusing should be used. The slit at the bottom of the workpiece is wider than the slit on the upper surface, which is favorable for discharging slag and oxygen to the bottom of the workpiece to participate in the total oxidation reaction. In a certain focus range, the bigger the positive focus is, the bigger the plate surface spot size is, the more adequate preheating and reheating around the cutting seam, the smoother and brighter the carbon steel cutting surface is.

More than 10000W laser pulse cutting stainless steel plate using positive focus cutting, cutting stability, conducive to slag discharge, not easy to reverse blue light.

Negative Focus Cutting

In this mode, because the focus is far away from the cutting surface, the cutting seam is wider than the cutting point on the surface of the workpiece.

When cutting stainless steel, should adopt the negative focus cutting, the cutting surface is even, the cutting section is good.

For the metal plate perforation before cutting, the minimum spot size and the maximum energy density can be ensured by using the negative focus because the perforation height is fixed. The deeper the hole, the bigger the negative focus.

Zero Focus Cutting

The cutting focus is on the workpiece surface, generally near the focus of the cutting surface is smooth, and away from the cutting focus of the lower surface appears rough.

Fiber laser cutting machine needs to use different focusing methods to process different workpieces. Because different types of cutting heads have different focusing positions and adjustment methods, users can choose according to the different effects of positive and negative focusing cutting stainless steel and carbon steel, combined with their own processing needs. Appropriate focusing cutting method to give full play to the performance advantages of the metal laser cutter.

Related Models: AF-E Series · AF-1390 Series

Video Reference

Please Share This

Get A Quick Quote Today!