How to clean the end face of optical fiber output head of fiber laser cutter

As a guided wave medium, optical fiber has high coupling efficiency, small core diameter, easy to form high power density in optical fiber, and high through power per unit area. In application, if the laser is not clean properly, the laser output head will burn out, affect the laser power output, affect the stability of the fiber laser cutting machine. Meanwhile, the maintenance cycle is long and the maintenance cost is high. Causing serious economic damage.

In order to ensure the long-term stability of the laser and the stability of the QBH output head, it is necessary to check whether there is dust or dirt on the fiber end face before connecting the fiber end to the optical head. If the end face of the fiber is dusty or unclean, it will contaminate the quartz column. It could seriously damage the laser.

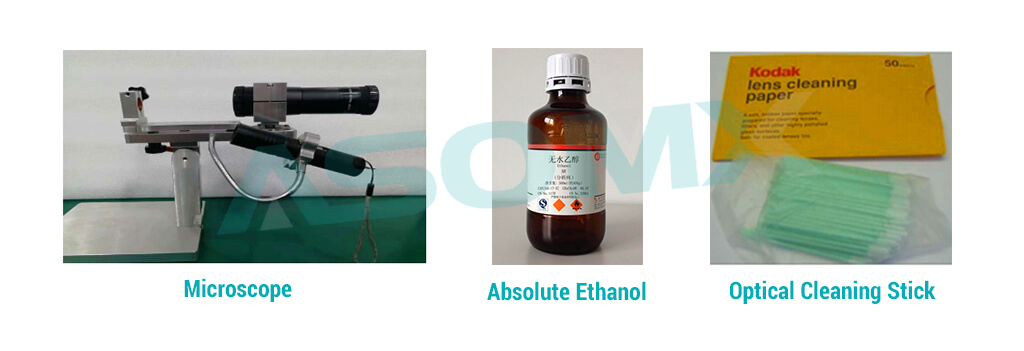

To clean the fiber end face, you need to prepare the following materials and tools

Operation Procedure

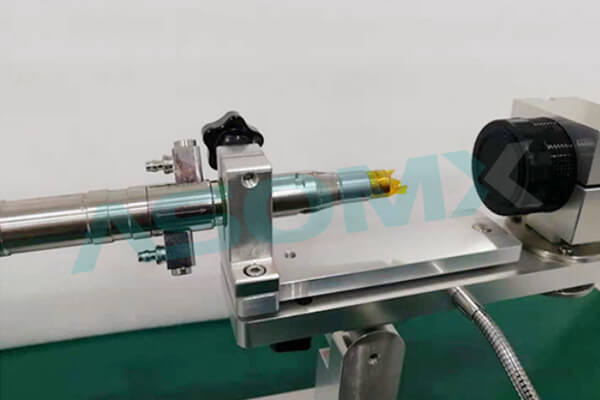

Choose no dust particles in the air, air dry space to clean the QBH output head. Place the microscope on a stationary, clean surface and maintain a comfortable posture for easy viewing and cleaning of the Quartz column end face. Attach the end of the fiber to the microscope mount as shown.

Fiber output head fixed to the fixed frame, it should be kept in a horizontal state to prevent the dust in the air from polluting the end face of the quartz column during the wiping process. Use compressed air to blow away the floating dust on the surface of the fiber end, and then carefully unscrew the protective cover from the fiber end.

Use the flashlight as an additional light source so that the light can be reflected from the fiber end into the microscope. Adjust to the position where the flashlight is irradiated from the side to the end face of the fiber head.

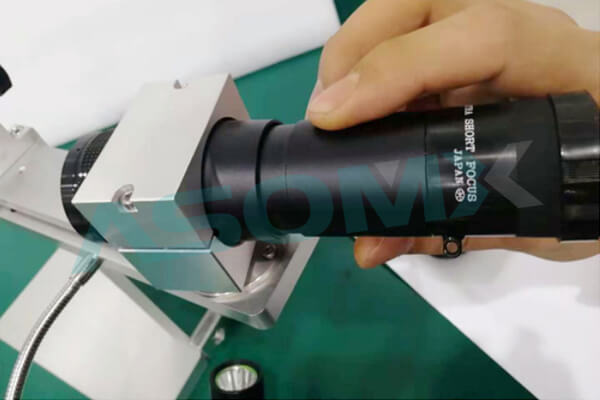

Adjust the focal length of the microscope so that its focus is exactly on the end face of the fiber, the end face of the quartz block. In this way, adjust the focus position of the microscope so that the quartz column can be clearly imaged.

Check the end face of the fiber carefully through a microscope. If there is visible contamination on the end face of the quartz, it must be cleaned.

Cleaning method for quartz column of optical fiber output head

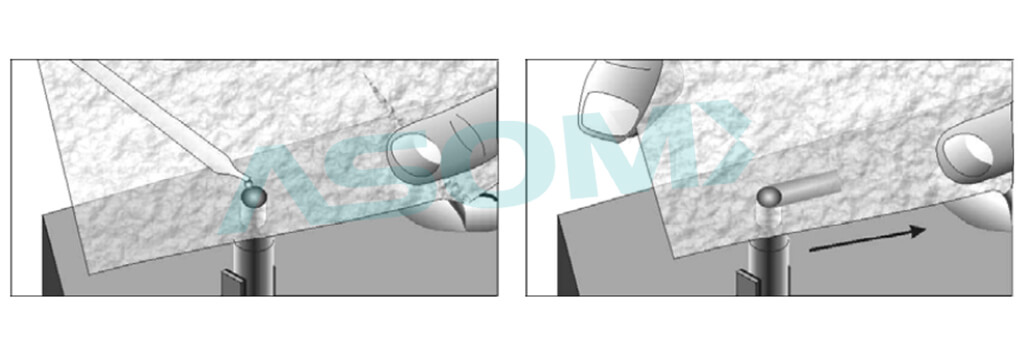

First, use clean compressed air to blow away the larger particles on the end surface, and then wipe with an optical cleaning stick. As shown, drop some isopropanol or anhydrous alcohol onto the optical cleaning rod and gently sweep the quartz block in a spiral manner. Be careful not to scratch the quartz surface. Never touch the cleaning stick with your finger. Each cleaning stick can only be used once.

If the optical cleaning stick can not remove the contamination spots, the lens paper should be used for scrubbing. As shown below, take a piece of Kodak lens tissue and put a drop of isopropyl alcohol on it. Then, wipe from one side of the fiber end face to the other side until the isopropyl alcohol on the end face is dry. After scrubbing, use an optical cleaning stick for local cleaning.

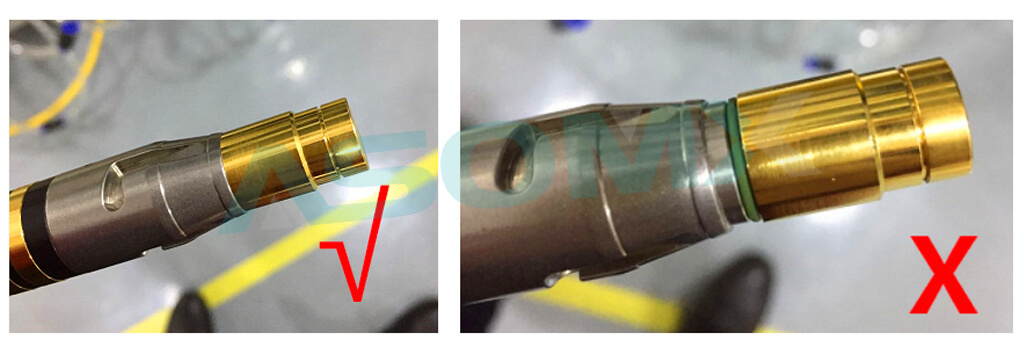

When installing the quartz protection part (similar to the nut part) of the fiber head, be sure to observe the fiber head with the microscope again to confirm it is completely clean. When installing the quartz protection part of the optical fiber output head, make sure that it is fixed in place to prevent serious loss caused by falling off during the application.

Points to note

The cleaned fiber end should be quickly installed in the QHB optical lens, long-time exposure to the air will cause secondary pollution. When inserting the optical lens, keep the output head and the optical lens inserted horizontally, and it is forbidden to insert the optical head vertically.

Be patient and careful in your operations. Also requires a clean environment around the workplace and auxiliary equipment. Only special lens paper can be used for cleaning. Excessive cleaning and improper cleaning can damage the fiber output head.

Related Models: AF-E Series · AF-R Series

Please Share This

Get A Quick Quote Today!