Factors affecting the welding effect of laser welding machine

Laser Power Density

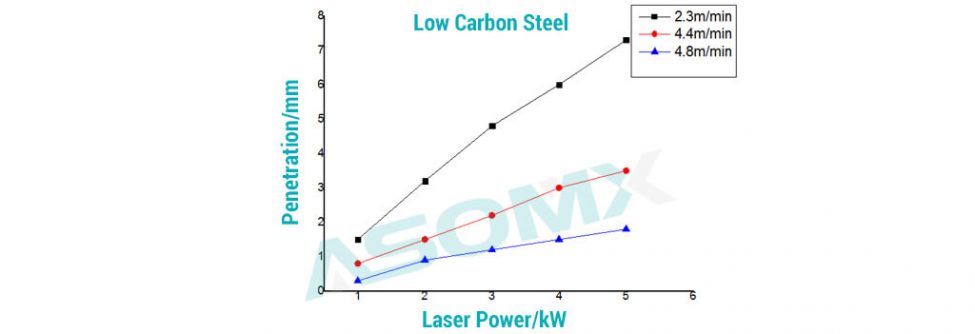

The premise of handheld laser welder deep penetration welding is that the focused laser spot has a high enough power density, so the laser power density has a decisive influence on the weld formation. The penetration depth and welding speed are controlled by the laser power. When the laser power is increased, the penetration depth and the welding speed are increased.

There is a critical value for the laser power to reach a certain weld penetration. When the critical value is reached, the weld pool boils violently, the weld penetration decreases sharply when exceeds. In addition, due to the action of metal vapor, the keyhole will be formed in the weld pool, and the keyhole is the key to realize deep penetration welding.

The focal spot power density is not only proportional to the laser power but also depends on the laser beam and the focusing path parameters.

Welding Speed

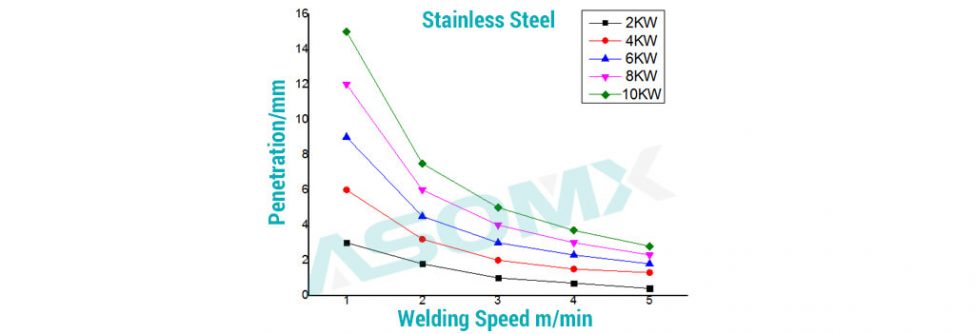

In the process of deep penetration welding, the welding speed is inversely proportional to the penetration. When the laser power is kept constant, if the welding speed is increased, the heat input will decrease and the penetration will also decrease. Therefore, properly reducing the welding speed can increase the depth of fusion, but too low speed will lead to excessive melting of materials. So, for the specific laser power, the specific thickness and the type of material, there is a maximum penetration of the appropriate welding speed range.

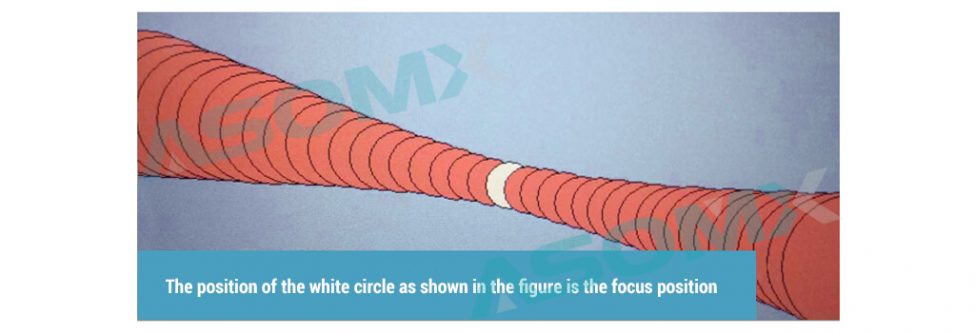

Focus Position

In deep penetration welding, the focus position is very important to maintain enough power density. The variation of the relative position between the focus and the surface of the workpiece directly affects the width and depth of the weld. Only when the focus is in a suitable position within the surface of the workpiece, can the parallel section be formed and the maximum penetration is obtained.

Protective Gas

The protective gas has two functions: one is to eliminate the air in the local area of the welding, to protect the working surface from oxidation, and the other is to suppress the plasma cloud produced during high power laser welding.

Workpiece Joint Gap

The gap between the workpiece and the assembly gap is directly related to the penetration depth of the welding workpiece and the width of the weld. During deep penetration welding, if the joint gap exceeds the spot size, it cannot be welded. If the joint gap is too small, sometimes the process will produce undesirable effects such as overlapping of butt plates and difficulty in fusion. If the joint gap is too large, it is easy to weld through. High-speed welding can make up for some weld defects caused by excessive gaps, while high-speed welding has narrower welds and stricter assembly requirements.

Material Nature

The efficiency of laser welding is determined by the absorption of laser by the material of the workpiece being welded. There are two factors that affect the absorption rate of laser by the material: one is the resistance coefficient of the material, which is found by measuring the absorption rate of polished surfaces of different materials, the absorptivity of the material to the laser is proportional to the square root of the resistance coefficient, which varies with temperature. Second, the surface state of the material has an important effect on the absorption of the light beam, so it has an obvious effect on the welding effect.

Video Reference

Please Share This

Get A Quick Quote Today!