Differences Between Single-mode and Multi-mode Fiber Laser Cutting Machine

After all, a high-power fiber laser source is the most expensive part of the whole cutting system, so many end-users will be the first to understand the configuration, performance, reliability, after-sales and other differences between different laser sources. We do some in-depth information, we hope that we can compare the system to understand the fiber laser source, help terminal customers correct selection.

Due to the excellent characteristics of fiber laser cutting machine, more and more end-users pay attention to and consider using the fiber laser cutter to replace the original processing method in metal processing. With the localization of high-power fiber laser sources, the cost of various core devices has been greatly reduced, so the selection threshold of high power fiber laser machines begins to disappear.

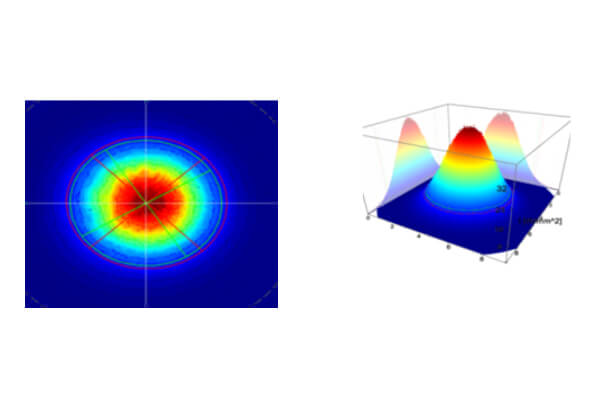

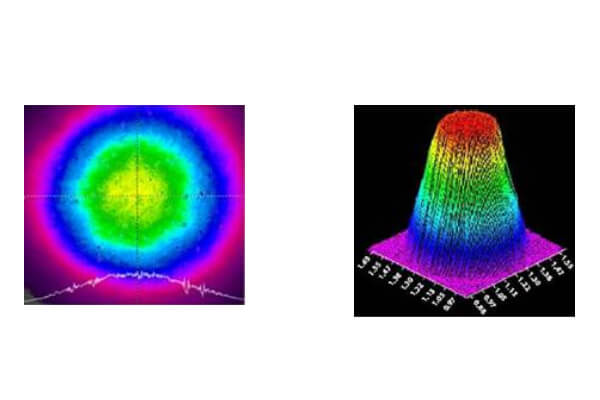

Comparison of Beam Quality Between Single-mode and Multi-mode

In the cutting application, the focus spot has a great influence on the cutting quality. The single-mode laser source has a thin core, the beam quality is better than the multi-mode, the energy distribution is Gaussian distribution, and the middle energy density is the highest, the three-dimensional image is a sharp round peak.

The fiber core of the multi-mode laser source is thicker, the beam quality is worse than that of the single-mode laser, the energy distribution is more average than that of the single-mode laser spot, the three-dimensional image is an inverted cup, judging from the steepness of the edge, the multi-mode is much steeper than the single-mode.

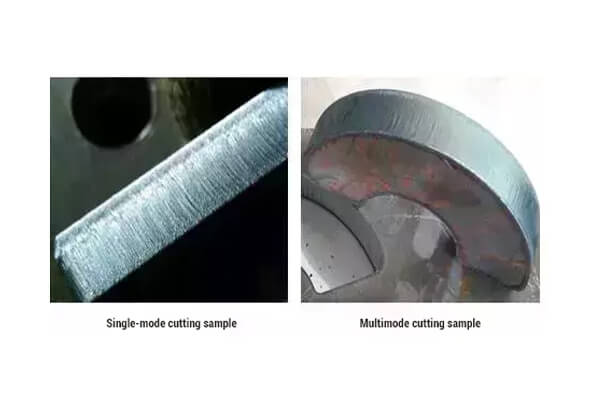

Comparison of 2kw Single-mode and 2kw Multi-mode Laser Cutting

1 mm thin plate cutting speed 20% higher than the multi-mode, visual effect is almost the same, but starting from 2 mm, the speed advantage gradually decreased, starting from 3 mm, regardless of speed or effect, the advantages of high power multi-mode laser source in terms of speed and effect are obvious, as shown in the following diagram:

So the advantage of single-mode source is in thin plate, and the advantage of multi-mode source is in thick plate. The choice of multi-mode or single-mode fiber laser source depends on the processing requirements of the actual terminal customers.

How To Choose Between Single-mode and Multi-mode Laser Source?

For the reason of low energy, the main processing material thickness of the laser source less than 2kw is inclined to thin plate, so the single-mode configuration of the laser source less than 2kw conforms to the actual market situation, more than 2kw laser power to cut thin and thick materials. From the whole processing industry, the improvement of processing quality is a rigid demand, can not compromise, so many high-power laser selection will not consider single-mode, must ensure processing quality first!

At the same time, the single-mode fiber core is generally thin, which means that the same power of laser transmission in the single-mode fiber core, the light energy load of the single-mode fiber core is larger, which is a test to the material, and when cutting high-reflective material, high-intensity reflected light and outgoing laser superimposed, if the tolerance of the fiber material is not enough, it will be very easy to burn the fiber core, and the life of the fiber core material is also a challenge! Therefore, many laser manufacturers in the configuration of high-power fiber laser sources still choose multi-mode configuration!

Related Models: AF-P Series · AF-G Series

Video Reference

Please Share This

Get A Quick Quote Today!