The importance of selecting the original wearing parts for laser cutting machine

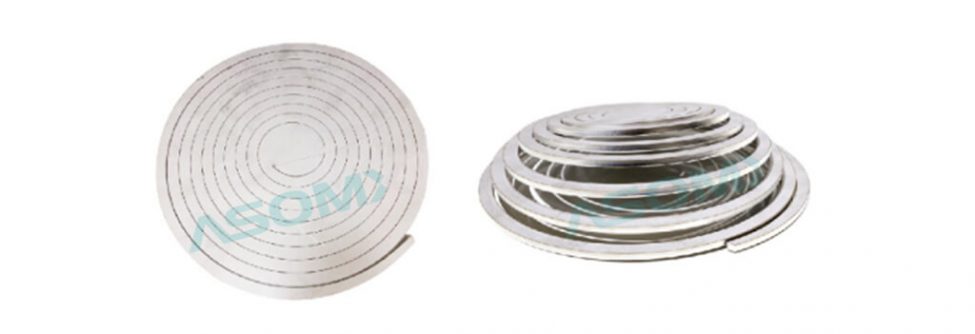

The cleanliness of the protective mirror directly affects the processing performance and quality of the laser cutting machine. If the lens is dirty, it will not only affect the cutting effect and efficiency, but also cause the internal parts of the cutting head and the laser output head to burn down, so the first need to use good material, high transmittance, small coefficient of thermal expansion, when the lens is dirty during processing, needs to be cleaned or replaced.

The processing of protective lenses has special technological requirements, from the selection of substrate materials, processing accuracy, surface defects, coating, stability, mechanical properties (specific gravity, brittleness, tensile strength, compressive strength, hardness). In order to reduce costs, low-quality protective lenses usually use ordinary base materials. The coating process is not guaranteed. The light transmittance is poor, heat-resistant, easy to break, unable to bear the penetrating force of the laser, resulting in exploding holes in the lenses, broken lens particles will contaminate the whole cutting head, which will damage the core high-value components, such as the focusing lens and the sensor. The maintenance cost will be as high as 20-50% of the new cutting head price, and it will delay the terminal production and cause greater economic losses.

The harmful consequences of using inferior protective lenses

The quality of the protective lens is poor, and the absorption rate of the laser will increase. After a long period of continuous irradiation, the temperature will rise and produce thermal deformation, which will cause the thermal lens effect and lead to the focus shift, the higher the power, and the processing of highly reflective materials, the faster the thermal expansion of optical elements is, the more obvious the thermal lens effect is.

When cutting stainless steel, thermal lens effect focal drift will result in inconsistent cutting section effect, more and more hanging slag. When cutting carbon steel, the thermal lens effect will cause the bottom to slag more and more, the metal can’t cut through.

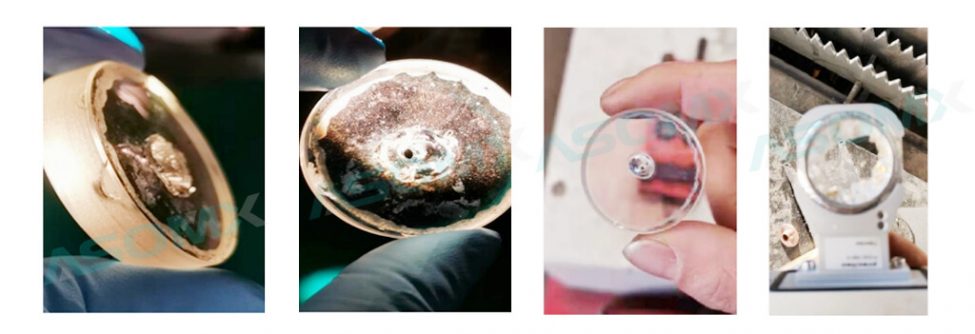

Burn-through of protective glasses

In the process of laser cutting, the low-quality protective lenses are easy to be burnt due to their poor ability to block dust and flying objects. For ultra-high power machining heads, the protective lenses should be carefully selected, under the action of a high-power laser, the bad protective lens will burn through directly.

Focus lens burning point

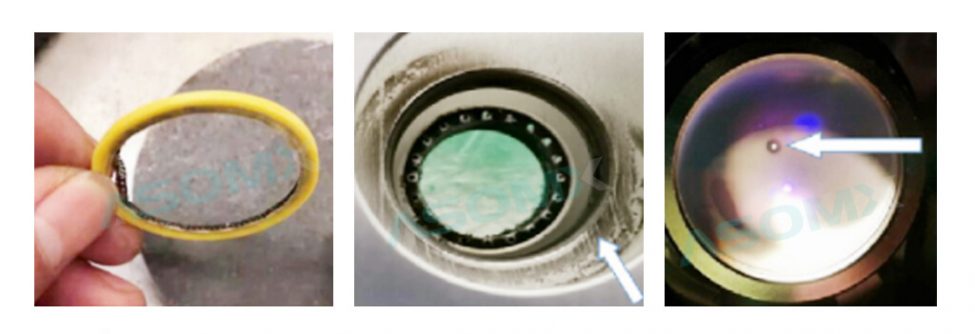

If it is not found in time after the protective mirror is burned out, the particles produced by continuous light processing and cutting will contaminate the mounting assembly, the sealing ring and the lower surface of the focusing mirror and cause the burning point on the surface of the focusing mirror, requires deep cleaning and replacement of the complete set of mounting assemblies and focusing modules.

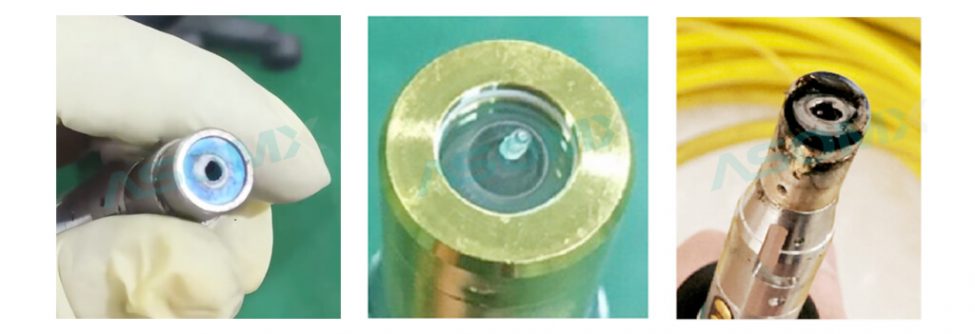

Laser output head is fried

For a high-power laser cutter, once the protective mirror burns through, it is easy to destroy the internal collimation and focusing mirror module of the cutting head in an instant. In the most serious case, when the optical elements in the cutting head are damaged, the optical path will be abnormal, and the return light will cause the window of the fiber output head of the laser to get abnormal heat, and finally burn out the QBH or LOE crystal, so the whole laser output head needs to be replaced.

The use of inferior protective lens not only affects the service life of the cutting head and causes all kinds of accidents, but also affects the processing progress and quality, thus increases the processing cost and reduces the benefit of the factory. Therefore, we suggest the user buy protective glasses and other vulnerable parts must be purchased through the manufacturer, do not lose big for small gain!

Related Models: Co2 Laser Cutter · Laser Marking Machine

Please Share This

Get A Quick Quote Today!