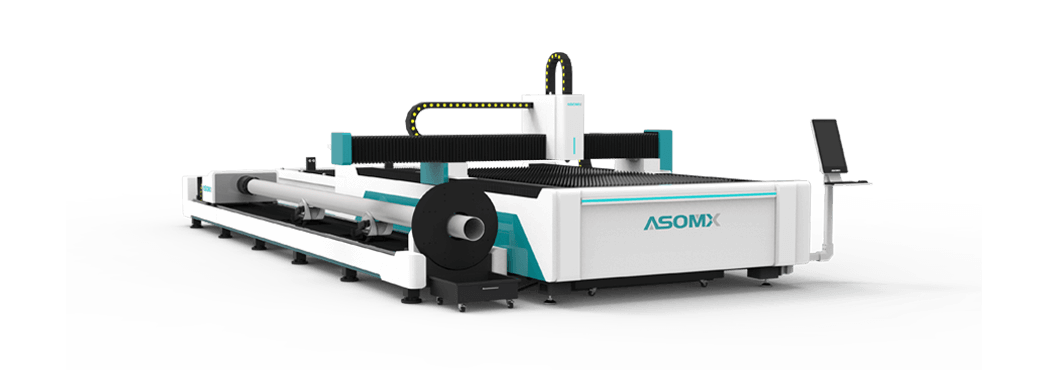

Features of CNC Laser Cutting Machine

- The machine bed is heated to 600 degrees and then cooled in the furnace for 24 hours. After cooling, processing the bed surface with a gantry milling machine to improve the accuracy, the strength and service life of the machine up to 20 years.

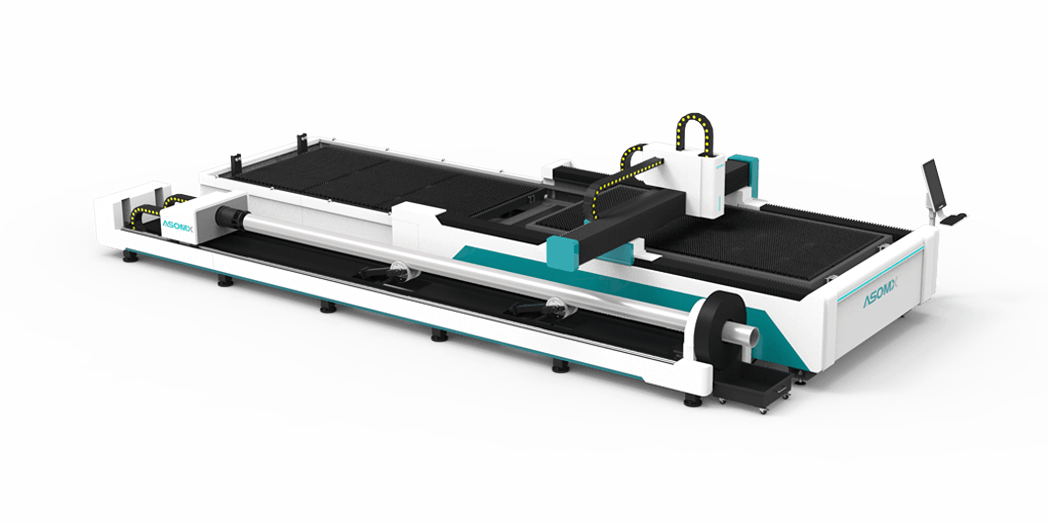

- Upper and lower exchangeable worktable, shortens the standby time, the drawer type material collection device makes the collection more convenient, effectively improves the efficiency above 50%.

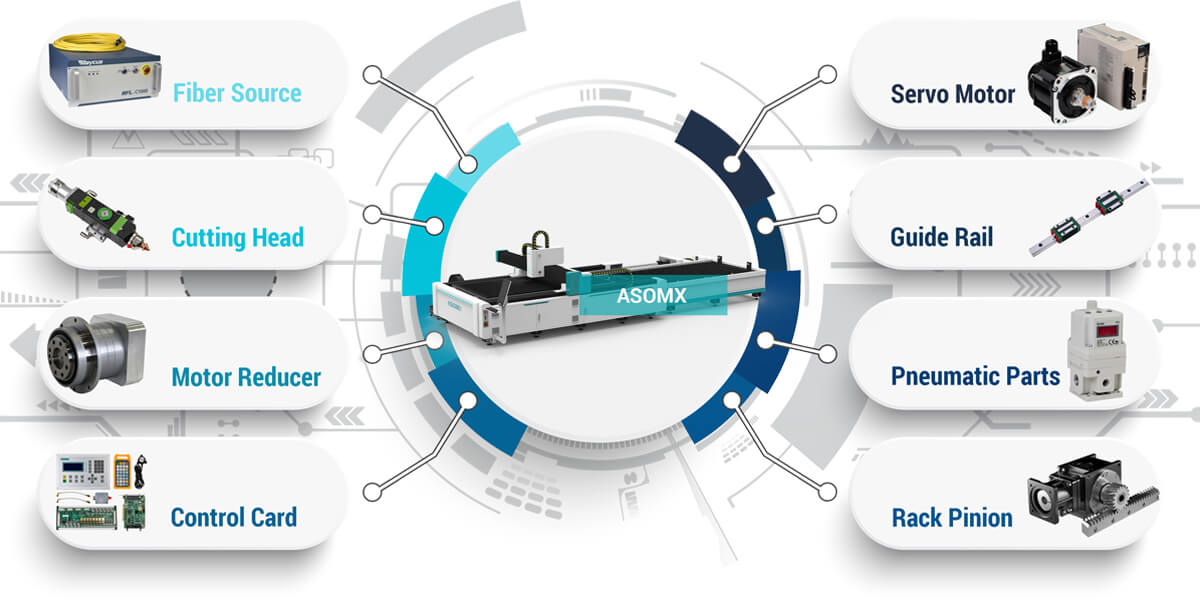

- Japan Yaskawa servo motor and drive system, to provide customers with faster speed and better stability.

- Optical fiber transmission, no need to adjust the laser path. IPG and Raycus fiber sources are used as the laser resonator.

- Swiss Raytools and German PRECITEC autofocus cutting head is controlled by the system, automatically adjust the focal length according to the thickness of the plate, which can read system storage parameters automatically and save time and manpower.

- The 360-degree radar system will predict and detect any obstacles, making the Z-axis high-speed to immediately avoid colliding obstacles.

- The rack and pinion drive system has better rigidity and higher precision saves feeding time and makes the operation more efficient. The maximum speed for platform switching is 10 seconds.

- Wireless remote control laser cutter, one-handed operation, magnetic design can be adsorbed on the machine body, available at all times.

- Aluminum alloy has the characteristics of lightweight and strong rigidity, which is good for high-speed movement in machining, and high flexibility is good for high-speed cutting based on high precision. The light beam can improve the running speed of the equipment, improve the processing efficiency and ensure the processing quality.

- Automatic edge tracking for both sheet and tube applications. By using a new method of graphics rendering and display, the pipe parts can be displayed both in-plane and in three dimensions.

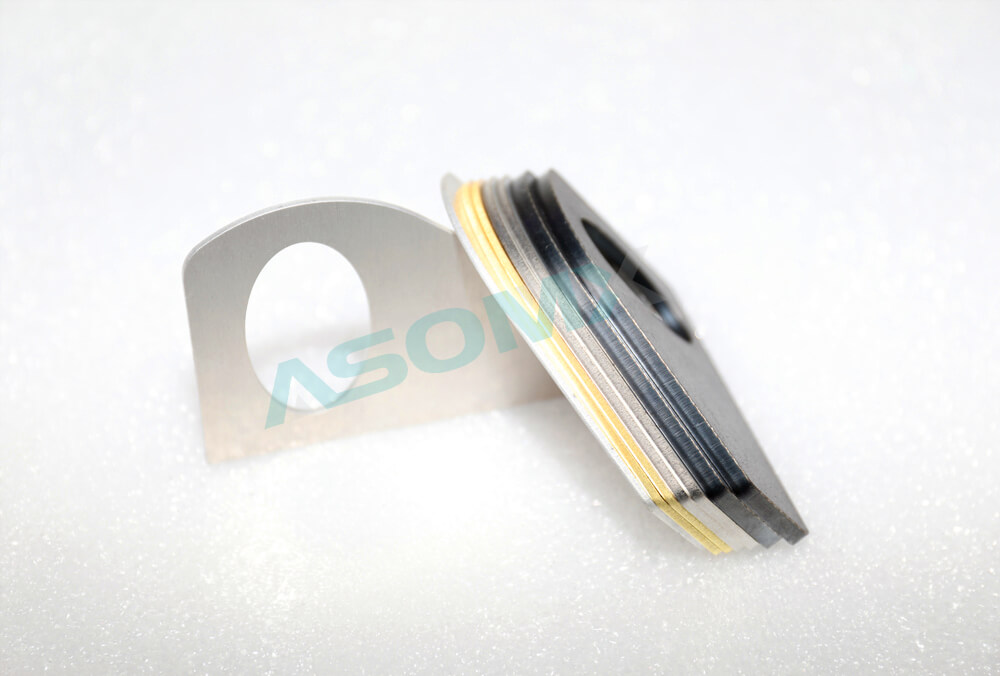

- Non-destructive clamping pipe, fast automatic centering clamping pipe, more stable performance. Small chuck size, a small moment of inertia, strong dynamic performance.

- Laser cutter has a perfect cooling system, lubrication system and dust removal system to ensure stable, efficient and lasting machine operation.

- Self-centering pneumatic chuck, gear transmission mode, high transmission efficiency, long service life, high reliability.

Product Details and Configuration

All the details and configuration can be customized according to your processing requirements

Aluminum alloy beam

1 of 8Switching platform

2 of 8Optic cable

3 of 8Display

4 of 8Platform limit

5 of 8Working table

6 of 8Support roller

7 of 8Pneumatic chuck

8 of 8Technical Parameters

| Model No. | AF-S Series |

|---|---|

| Laser Power | 1000W - 8000W |

| Laser Wavelength | 1080±10nm |

| Laser Type | Single-Core Junction Semiconductor Module |

| Cutting Head | Swiss Raytools / German Precitec |

| Working Range | 1500mm*3000mm |

| Optional Range | 1500mm*4500mm / 2000mm*4000mm / 2000mm*6000mm |

| Min. Line Width | ≤0.1mm |

| Worktable Max. Load | 1000kg |

| Max. Acceleration | 1.5G |

| Max. Moving Speed | 120m/min |

| Control System | Cypcut System / Cyptube System |

| Positioning Accuracy | ±0.01mm |

| Repeatability Accuracy | ±0.02mm |

| Cooling Type | Industrial Circulating Water Cooling |

| Graphic Format Supported | DST, PLT, BMP, DXF, DWG, AI, JPG, DXP, PGN, TIF, LAS, etc. |

| Compatible Software | CORELDRAW, PHOTOSHOP, AUTOCAD, ARTCUT, etc. |

| Electricity Supply | 220V/380V±10% 50/60Hz |

| Unit Power | 19.3kw/21.8kw/26.5kw/29.6kw/33.4kw/41.4kw/52kw |

| Auxiliary Gas | Compressed Air / Nitrogen / Oxygen |

| Operating Temperature | 0°C-45°C |

| Working Humidity | 45%-95% no condensed water |

| Laser Module Life | 100000hours |

| Gross Weight | 7500kg |

| Package Dimensions | 7970*3650*2050mm |

Delivering Precise and Consistent Cutting for Metal

Industrial-grade components give you faster motion, better accuracy and increased laser power

Unparalleled Cut Quality and Consistency

Industry-leading performance at an affordable price, ASOMX laser ensures accuracy and longevity with multiple power options

Contact Us

Get your free quote, expert advice today.